The construction industry is currently standing at the edge of a massive technological paradigm shift that promises to redefine how we build our cities. For decades, the sector has struggled with stagnant productivity rates and a growing shortage of skilled labor, creating a bottleneck for global infrastructure development. However, the emergence of autonomous construction machinery is providing a high-tech solution to these age-old industrial challenges. These machines are not just remotely controlled robots; they are intelligent systems capable of perceiving their environment and making real-time decisions.

By integrating advanced sensors, artificial intelligence, and satellite positioning, autonomous equipment can perform repetitive tasks with a level of precision that humans simply cannot match. This revolution is about more than just speed; it is about creating a safer, more sustainable, and highly predictable building process. As we move away from traditional manual operation, the role of the construction worker is evolving into that of a high-level systems operator. This guide explores the mechanical and digital heart of this transformation, looking at how self-driving bulldozers and robotic masons are building the future. Understanding these innovations is essential for any professional looking to stay relevant in the rapidly modernizing world of architecture and civil engineering.

The Core Technologies Powering Autonomy

Autonomous machinery relies on a “brain” that combines multiple data streams to understand its position and the work required. This technical foundation is what allows a ten-ton excavator to move with the grace of a surgeon.

A. GNSS and High-Precision Positioning

Global Navigation Satellite Systems (GNSS) provide the machine with its exact coordinates on the planet. When paired with local base stations, these systems achieve centimeter-level accuracy, ensuring every trench is dug exactly to the blueprint.

B. Computer Vision and LiDAR Scanning

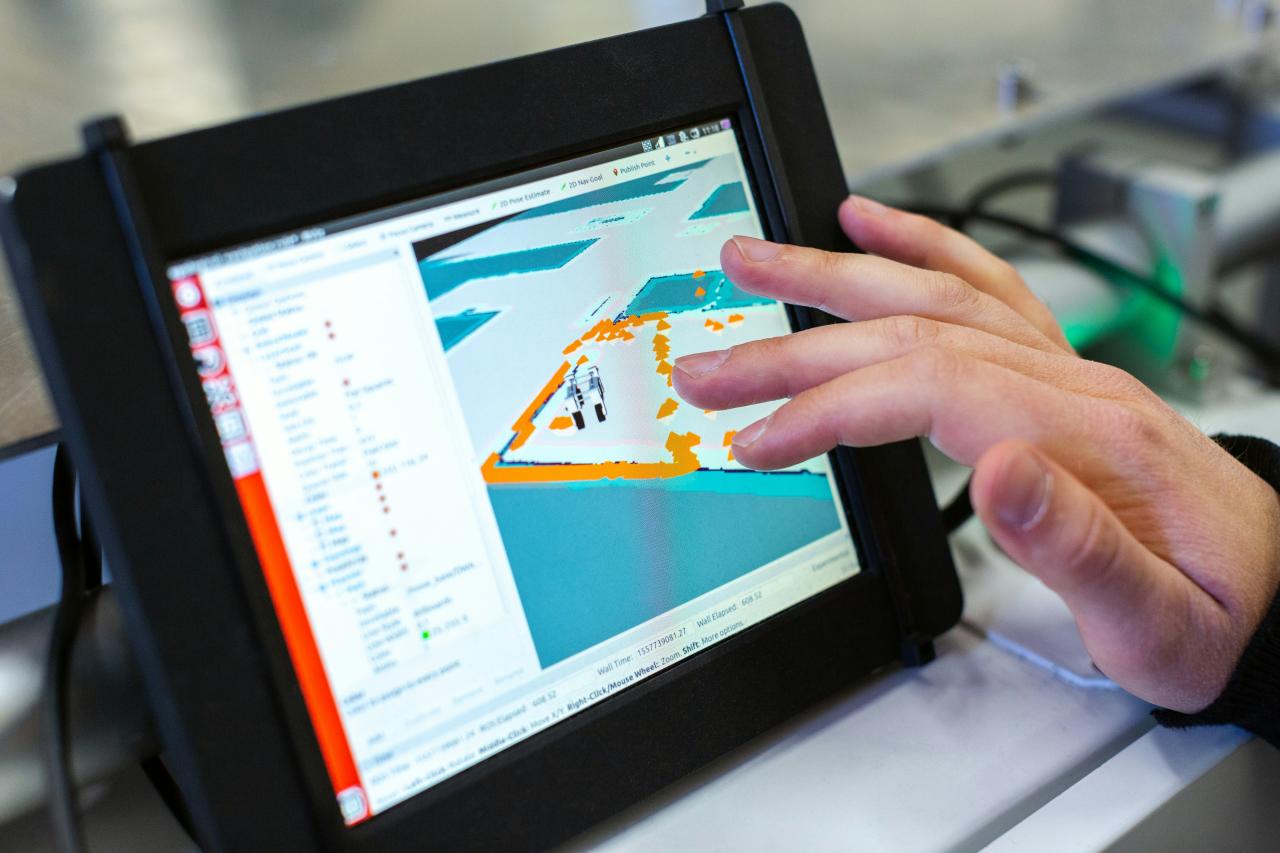

Cameras and Light Detection and Ranging (LiDAR) act as the machine’s eyes, scanning the job site for obstacles and terrain changes. This creates a real-time 3D map that allows the AI to navigate complex environments without hitting workers or other equipment.

C. On-Board Artificial Intelligence Units

The AI processes sensor data to make split-second decisions, such as adjusting the blade angle of a grader to meet a specific slope. These algorithms learn from every movement, constantly optimizing the path of the machine for maximum fuel efficiency.

Key Benefits of Jobsite Automation

The primary goal of adopting autonomous machinery is to solve the most pressing logistical and financial problems facing modern construction firms. The benefits are measurable and immediate.

A. Unmatched Operational Efficiency

Autonomous machines do not need breaks, lunch hours, or sleep, allowing for 24/7 operation in certain environments. This drastically shortens project timelines, which is a massive financial win for developers and contractors.

B. Enhanced Safety and Risk Mitigation

By removing human operators from dangerous zones, companies can significantly reduce the number of jobsite accidents. Machines can work in unstable terrain or extreme weather conditions that would be too risky for a human.

C. Precision and Waste Reduction

Robotic systems follow digital models perfectly, eliminating the “re-work” that often happens due to human error. This precision saves thousands of dollars in wasted materials and fuel costs over the life of a project.

Major Types of Autonomous Equipment

The revolution is touching every corner of the fleet, from the machines that move dirt to the ones that lay the final bricks. Each type of equipment requires a specialized set of autonomous protocols.

A. Autonomous Earthmovers and Excavators

These are the workhorses of the industry, now capable of grading land and digging foundations based on a GPS map. They can communicate with autonomous dump trucks to coordinate a seamless flow of material removal.

B. Robotic Masonry and Concrete Systems

Machines are now capable of laying bricks faster and more accurately than any human team. Specialized concrete printers are also being used to “print” entire walls directly on-site using sustainable materials.

C. Self-Driving Transport and Haulage

Large-scale mining and infrastructure projects use autonomous trucks to move massive loads across pre-defined paths. These systems optimize the route to minimize tire wear and maximize fuel economy.

Integration with Building Information Modeling (BIM)

BIM is the digital blueprint of a project, and it serves as the primary source of instructions for autonomous machinery. The connection between the office and the field is now a real-time data loop.

A. Translating 3D Models into Machine Tasks

Engineers upload BIM files directly to the machine’s control system, giving it a perfect digital world to follow. The machine then executes the physical work based on these exact geometric coordinates.

B. Real-Time Progress Tracking

As the machine works, it sends data back to the BIM software, allowing managers to see exactly how much work has been completed. This “digital twin” of the jobsite is updated every few seconds.

C. Automated Conflict Detection

If a machine encounters an underground pipe not found in the digital model, it can stop and alert the engineering team instantly. This prevents costly damage and allows for immediate adjustments to the digital plan.

Addressing the Skilled Labor Shortage

The construction industry is facing a massive “silver tsunami” as experienced operators retire, leaving a gap that younger generations are not filling. Automation is the bridge across this gap.

A. Augmenting the Existing Workforce

Autonomy is not about replacing people but about making the current workforce more productive. One skilled operator can now oversee a fleet of three or four autonomous machines simultaneously.

B. Lowering the Barrier to Entry

Operating a traditional excavator takes years of practice to master, but monitoring an autonomous one requires a different, more tech-centric skill set. This attracts younger, tech-savvy workers back into the construction industry.

C. Reducing Physical Strain and Burnout

By automating the most repetitive and physically demanding tasks, companies can keep their older, more experienced workers in the industry longer. These experts can focus on strategy and problem-solving rather than manual labor.

The Role of Connectivity and 5G

For a fleet of autonomous machines to work together, they need a high-speed, low-latency communication network. 5G technology is the “glue” that holds the autonomous jobsite together.

A. V2X (Vehicle-to-Everything) Communication

Machines need to talk to each other to avoid collisions and coordinate tasks. 5G allows for massive amounts of data to be shared instantly between different pieces of equipment.

B. Remote Operation and Tele-Operation

In very complex scenarios, a human can take control of a machine from thousands of miles away using VR goggles and low-latency controls. This allows a single expert to assist projects across the globe from a central office.

C. Edge Computing for Real-Time Decisions

Processing all that data on the machine itself (the “edge”) is faster than sending it to a distant server. 5G enables this rapid processing, allowing the machine to react to a moving object in milliseconds.

Sustainability and Environmental Impact

Construction is one of the world’s largest emitters of carbon, but autonomous technology offers a path toward a much greener footprint. Efficiency is the key to environmental protection.

A. Optimized Fuel Consumption

AI algorithms calculate the most efficient path for every movement, reducing unnecessary engine idling and fuel burn. This can lead to a ten to fifteen percent reduction in total project emissions.

B. Support for Electrified Machinery

Autonomous systems are perfectly suited for electric powertrains, as the computer can manage the battery usage much better than a human. This accelerates the shift toward zero-emission jobsites.

C. Reduced Material Waste through Precision

When every cut and every pour is perfect, the amount of wasted concrete, steel, and wood drops significantly. This reduces the carbon footprint associated with producing those materials in the first place.

Challenges to Widespread Adoption

While the technology is impressive, there are still significant hurdles that must be cleared before every jobsite becomes fully autonomous. These challenges range from technical to legal.

A. High Initial Capital Investment

The cost of purchasing autonomous equipment is much higher than traditional machinery. While the long-term ROI is clear, the upfront cost can be a barrier for smaller construction firms.

B. Cybersecurity and Data Protection

As construction sites become digital, they also become targets for hackers. Protecting the software that controls ten-ton machines is a critical safety and security priority.

C. Regulatory and Liability Frameworks

If an autonomous bulldozer has an accident, who is responsible? The industry is still working with governments to create new laws that govern the use of robotic equipment on public roads and jobsites.

The Future of Autonomous Civil Engineering

We are moving toward a world where the entire lifecycle of a project—from surveying to final paving—is handled by a coordinated swarm of robots.

A. Autonomous Site Surveying Drones

Drones are already being used to create 3D maps of sites before work even begins. In the future, these drones will act as the “scouts” for the ground-based autonomous fleet.

B. Swarm Robotics for Modular Construction

Smaller robots working in a “swarm” could eventually assemble complex structures much like ants build a colony. This would allow for highly complex designs that are currently impossible to build by hand.

C. Self-Healing Infrastructure

Future autonomous machines might not just build roads but also maintain them. Small robots could be deployed to find and fix potholes automatically before they become a major problem.

Implementing Autonomy in Your Fleet

For companies ready to make the jump, the transition to autonomy should be a gradual process that focuses on the highest-impact areas first.

A. Starting with “Operator Assist” Features

You don’t have to go fully autonomous overnight. Many companies start with “semi-autonomous” features like grade control, which assists the human operator in being more precise.

B. Developing a Data-Centric Workforce

The most important part of the transition is training your team to work with data. Your future foremen will need to be as comfortable with a tablet as they are with a shovel.

C. Partnering with Tech-Forward Manufacturers

Choosing the right equipment partner is vital. You need a manufacturer that offers robust software support and regular “over-the-air” updates to keep your fleet at the cutting edge.

Conclusion

Autonomous machinery is fundamentally changing the DNA of the construction industry. The integration of LiDAR and GNSS allows for a level of precision that was once thought to be impossible. Efficiency gains from 24/7 operation are helping to solve the global infrastructure crisis one project at a time. Safety is the most important byproduct of automation, as we remove humans from high-risk environments. Sustainable building practices are now easier to achieve thanks to the fuel-saving algorithms of AI.

The workforce is not disappearing; it is evolving into a more technical and high-value role. Connectivity via 5G is the essential foundation that allows these machines to communicate and collaborate. Initial costs remain high, but the long-term return on investment is becoming undeniable for large firms. Legal and regulatory frameworks must keep pace with the rapid speed of mechanical innovation. Data is now just as important as steel and concrete in the successful completion of a modern project.

BIM models are no longer just pictures; they are the living brains of the autonomous jobsite. Small-scale robotics and drone integration are the next frontiers of the autonomous revolution. Construction firms that ignore these trends risk being left behind in a highly competitive market. The ultimate goal of this technology is to create a built environment that is more resilient and affordable. The future of architecture is being written in code and executed by autonomous steel.