Modular construction, a modern building methodology often referred to as off-site construction or prefabrication, has emerged as a revolutionary answer to the inefficiencies that plague the conventional building sector.

Moving a significant portion of the construction process from the often-unpredictable job site into a controlled factory environment dramatically changes the equation for project managers, developers, and investors alike.

This shift fundamentally redefines how projects are budgeted and scheduled, consistently proving that adopting a modular approach is one of the most effective strategies for slashing both project costs and completion times.

The construction industry is constantly seeking ways to enhance efficiency, reduce waste, and improve quality control, all while navigating the volatility of labor markets and material supply chains.

Traditional, or “stick-built,” construction is notoriously susceptible to costly delays caused by adverse weather, on-site mistakes, theft, and subcontractor scheduling conflicts.

Modular construction bypasses many of these issues, offering a predictable, streamlined, and optimized manufacturing process that translates directly into superior financial performance and faster occupancy.

The Economics of Off-Site Manufacturing: Deep Diving into Cost Savings

The core economic advantage of modular construction stems from its factory-based system.

Unlike a chaotic, exposed job site, a controlled manufacturing facility allows for the implementation of lean manufacturing principles, which are designed to eliminate waste and maximize efficiency.

This section unpacks the specific mechanisms through which modular building delivers profound cost reductions.

Predictable Cost Reduction Factors

Several key factors contribute to the significant cost savings achieved through the modular method. By isolating the construction process, companies can exert control over variables that are typically uncontrollable in a traditional setting.

A. Bulk Material Procurement and Stable Pricing

Modular manufacturers operate on a scale that allows them to purchase materials in massive bulk quantities. This not only secures significant volume discounts but also stabilizes material costs for the duration of multiple projects, offering a hedge against market volatility.

Furthermore, in a factory setting, materials are stored securely and protected from weather damage, theft, and unnecessary waste, which are common and unbudgeted expenses on a traditional site.

The precise, repetitive nature of factory assembly also allows for a highly accurate calculation of material needs, virtually eliminating over-ordering.

This efficient supply chain management means less capital is tied up in excess inventory and less material is scrapped.

Developers gain confidence from fixed-price contracts based on stable, pre-negotiated material costs, removing one of the biggest risks in traditional construction budgeting.

B. Optimized Labor Efficiency and Focused Wages

The workforce in a modular factory often consists of highly-skilled, full-time employees—salaried technicians and builders who specialize in repetitive, high-quality module assembly.

This contrasts sharply with the traditional model that relies heavily on a complex hierarchy of subcontractors and specialized trades hired at varying rates.

The factory environment eliminates non-productive time associated with travel to and from the site, waiting for other trades to finish, and weather-related shutdowns. This focused, productive labor pool directly lowers overall labor costs per square foot.

Since work is indoors, multi-trade coordination is simplified; plumbers, electricians, and drywall installers work in sequence, protected from wind, heat, or rain, significantly boosting productivity.

This guaranteed workflow means fewer labor hours are wasted, translating to a substantial decrease in the labor component of the project budget.

C. Minimization of Construction Waste and Disposal Costs

The statistics on waste in traditional construction are staggering, with studies showing that construction and demolition waste constitutes a massive portion of municipal solid waste.

Modular facilities are designed with waste reduction in mind. Cut-offs and excess materials are immediately categorized and re-integrated into the system or recycled, thanks to precise computer-aided design (CAD) cutting and material management systems.

This systematic approach drastically reduces material expenditures and the costly fees associated with site waste disposal.

By optimizing the use of every sheet of drywall or lumber, the factory process achieves material efficiency rates far superior to those on an open site, offering both an economic and an environmental win.

The cost savings from reduced disposal fees alone can be significant on large-scale projects.

D. Mitigation of Financially Draining Delay-Related Expenses

Time is, perhaps, the most significant factor in construction cost overruns. Every day a project is delayed incurs additional costs for site rentals, equipment leases, supervisory wages, extended financing interest, and potential penalties for late delivery.

Since 80-90% of the build occurs off-site, and the foundation work can happen simultaneously with module construction, the total timeline can be cut by 30% to 50%.

This rapid completion schedule minimizes the exposure to financially draining delays.

The factory schedule is impervious to local weather patterns or on-site labor disputes, providing a level of schedule predictability that is invaluable for budgeting and managing project risk.

Speed, Schedule, and Maximizing Return on Investment (ROI)

The accelerated schedule of modular construction is not just a marginal improvement; it’s a powerful financial lever that drives a faster Return on Investment (ROI) for property owners and developers.

The ability to occupy a building months sooner can be the difference between a project’s success and its failure for commercial, hospitality, and residential ventures.

The Financial Impact of Accelerated Occupancy

The time savings in modular construction translate directly into revenue generation and reduced carrying costs. This financial advantage is critical in today’s fast-paced market.

A. Faster Revenue Streams

For commercial projects—such as hotels, student housing, multi-family apartments, and hospitals—every month of early completion means one more month of rental income, room bookings, or patient revenue.

If a $20 million apartment complex can be finished four months ahead of a traditional schedule, the developer saves on four months of interest payments and gains four months of rental income, dramatically improving the project’s internal rate of return (IRR).

This speed ensures capital is deployed effectively and recouped quickly.

B. Reduced Interest and Carrying Costs

Construction loans carry interest, and the longer the construction phase, the greater the total interest paid.

By cutting the project timeline by a third or more, modular construction significantly reduces the total interest burden, a direct cost saving that can amount to hundreds of thousands or even millions of dollars on a large project.

Furthermore, reduced time on site means lower expenses for security, temporary utilities, site management, and equipment rentals.

C. Superior Schedule Certainty

Financial institutions and investors favor projects with low risk. Modular construction offers an unprecedented level of schedule certainty because the primary work is done in a controlled, predictable manufacturing environment.

This reliability lowers the perceived risk of the project, often leading to more favorable financing terms and increased investor confidence—another indirect but powerful cost advantage.

The Power of Concurrent Workflows

The greatest efficiency gain comes from parallel processing. In traditional building, activities are sequential: the foundation must be completed before framing can begin, and the structure must be watertight before interior trades start. In modular construction, two major workstreams run concurrently:

A. On-Site Preparation and Infrastructure Development

While modules are being fabricated in the factory, the on-site crew prepares the foundation, utilities, and crucial infrastructure.

This includes pouring concrete, laying utility lines (water, sewer, electric), and preparing access roads.

This is a traditional process, but it is completed without the added complication of coordinating with the above-ground building schedule.

B. Factory Fabrication and Advanced Fit-Out

In the controlled environment, modules—complete with installed electrical wiring, plumbing systems, HVAC components, and often full interior finishes, fixtures, and even furniture—are constructed simultaneously.

This means that when the module leaves the factory, it is close to 90% complete.

This high degree of finish significantly compresses the final on-site installation and commissioning time.

Once both are complete, the modules are transported and assembled on-site like massive building blocks, a process that can take days or weeks, not months.

This minimal on-site assembly time is the final, dramatic acceleration point, ensuring a building begins generating income far sooner than its traditional counterpart.

Enhanced Quality, Durability, and Long-Term Value

While cost is a primary driver, the improved quality and consistency of modular units further contribute to long-term financial stability by reducing maintenance, defect remediation costs, and improving energy performance.

A Controlled Environment for Superior Builds

The factory setting allows for stringent quality control that is impossible to maintain on an open construction site. This quality is systematically built into the process, lowering the life-cycle costs of the building.

A. Consistent Manufacturing Processes and Quality Assurance

All assembly line workers adhere to standardized, documented procedures, often guided by advanced digital templates and robotic assistance.

This consistency reduces human error and ensures that every module is built to the exact same high specifications, regardless of external conditions.

Dedicated quality control checks are integrated at every stage, from framing to final paint, ensuring defects are caught and rectified immediately within the factory, before they become expensive problems on-site.

This proactive approach significantly reduces post-occupancy warranty claims and punch-list items.

B. Protection from Environmental Damage

Materials and assemblies are never exposed to rain, snow, or extreme temperatures, which can compromise the integrity of lumber, gypsum, concrete, and adhesives in traditional construction.

Building in a climate-controlled space prevents moisture-related issues, such as mold, mildew, and material warping, before they can even begin.

This environmental protection ensures a superior, healthier, and more durable final product, reducing future maintenance costs related to structural or moisture-related failures.

C. Structural Integrity Built for Transit

A crucial, often-overlooked quality benefit is the inherent strength of modular units. They are built to withstand the stresses of transportation and craning—being lifted, loaded onto trucks, and set into place.

This necessitates a more robust framing and joint system than is typically used in stick-built construction.

This added structural reinforcement often translates to superior durability, better seismic resistance, and increased longevity, all of which reduce future repair and insurance expenses.

Long-Term Financial and Operational Benefits Beyond the Build

The cost-cutting advantages of modular construction extend far beyond the initial construction phase, providing long-term operational savings and improved sustainability, appealing greatly to investors with a long-term holding strategy.

Sustainability and Continuous Energy Efficiency Savings

Modular buildings are leading the way in sustainable construction, a factor that is increasingly important for regulatory compliance and long-term operating budgets.

A. Superior Thermal Performance and Lower Utility Bills

The precision engineering of modular components results in exceptionally tight building envelopes. Joints are sealed perfectly, and insulation is installed uniformly, minimizing air leaks and thermal bridging.

This superior airtightness leads to substantially lower energy consumption for heating and cooling, providing significant and continuous utility cost savings for the life of the building.

In a large commercial structure, these savings alone can quickly recoup any potential initial premium costs.

Furthermore, many modular designs are optimized for passive heating/cooling and the easy integration of solar panels or other green technologies.

B. Reduced Operational Carbon Footprint

By significantly cutting material waste, minimizing the need for heavy machinery operation on-site, and reducing the overall number of vehicle trips to and from the site, modular construction has a demonstrably lower carbon footprint than traditional methods.

This aligns with modern corporate and municipal sustainability goals, which can also translate into access to green building incentives, tax credits, and favorable “green financing” options—yet another financial advantage.

The certification process for programs like LEED is often simpler because of the standardized, documented material usage and factory quality control.

Flexibility, Adaptability, and Enhanced Asset Value

The very nature of modular design allows for unparalleled flexibility in the future, which provides an excellent financial safeguard and enhances the building’s asset value.

A. Easy Expansion, Reduction, and Reconfiguration

Modular buildings are inherently designed to be flexible. If a business needs to expand its office space, new modules can be built and seamlessly integrated into the existing structure with minimal disruption to ongoing operations.

This process is much faster and cleaner than a traditional renovation or addition. Conversely, if space needs to be reduced, modules can be safely disassembled and removed.

This adaptability is crucial in dynamic markets like healthcare and education, where needs change rapidly, offering a future-proofing element that protects the original investment.

B. Relocation and High Asset Reusability

Crucially, modular buildings are inherently designed to be disassembled and relocated if the land use changes or the business moves.

This capability makes them an ideal solution for temporary structures, remote industrial sites, or urban infill projects where land is eventually sold for other uses.

The high degree of material and structural reusability means the building retains a strong residual asset value, essentially turning the structure into a tangible, movable asset—a benefit unheard of in traditional, permanent construction.

The Technology and Future of Modular Construction

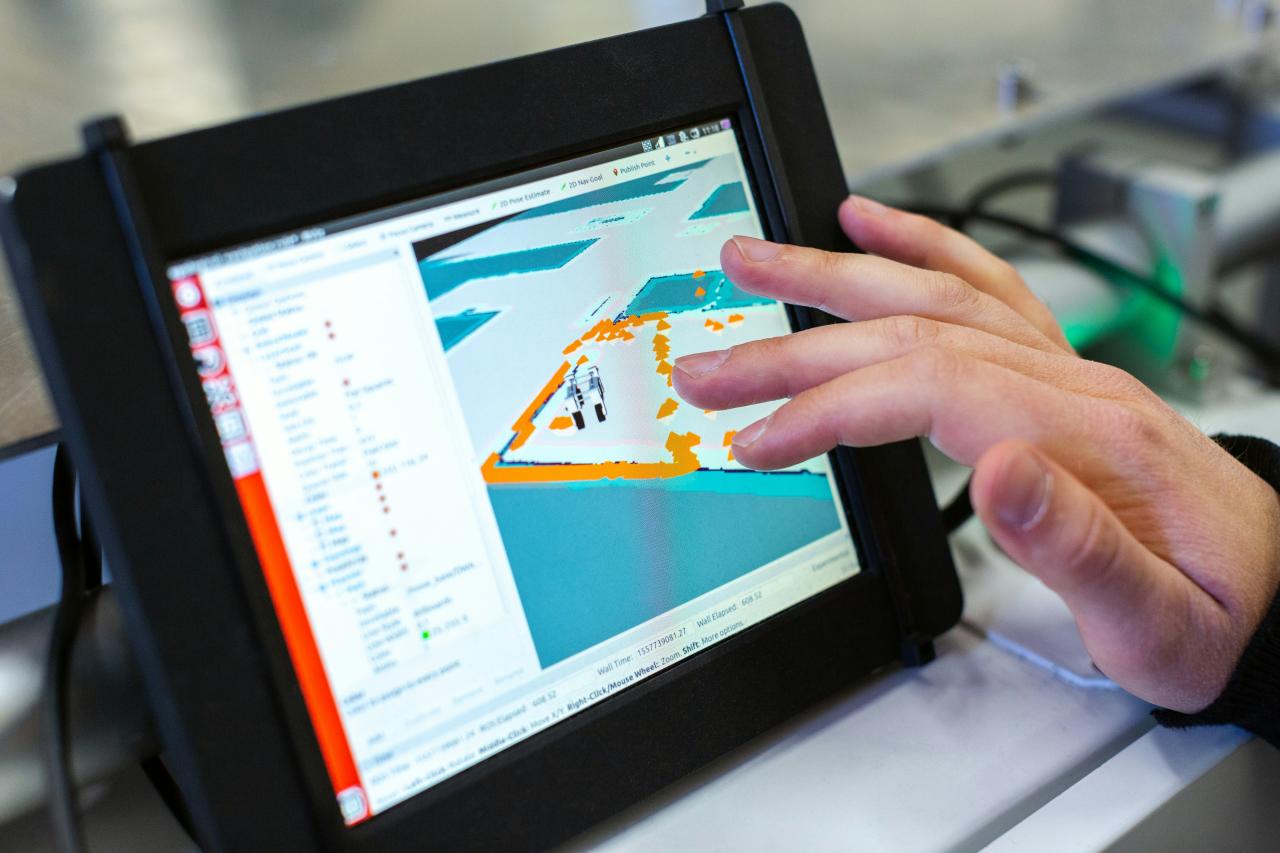

The efficiency and cost benefits of modular building are continuously being amplified by technological advancements. The image of the “prefab” building of the past is fundamentally obsolete.

Integrating Digital Design and Robotics

Modern modular facilities are not just assembly lines; they are high-tech manufacturing plants that utilize the latest digital tools to drive efficiency.

A. Building Information Modeling (BIM)

The entire building process begins with BIM software. This three-dimensional, intelligent modeling allows designers to virtually construct the entire building and break it down into modules.

This digital twin identifies every component, material conflict, and dimensional issue before construction begins, eliminating costly on-site change orders and mistakes—a major source of budget overruns in traditional builds.

B. Automated Production and Precision

Modular factories increasingly use robotics and automated machinery for repetitive and high-precision tasks, such as cutting lumber, welding steel frames, and positioning components.

This automation ensures accuracy far exceeding manual labor, which minimizes material wastage and guarantees component fit, accelerating the final assembly. The combination of precision and speed further solidifies the cost advantage.

Overcoming Perceptions: Quality and Aesthetics

Early challenges for modular construction included perceptions of low quality and standardized, uninspired aesthetics. Today’s reality is entirely different.

A. Customization is Key

Modern modular systems offer an enormous range of finishes, facades, and custom designs. They can incorporate brick, glass, wood, and metal cladding to achieve any architectural look, from sleek contemporary to traditional.

The standardization is in the process, not the product’s final appearance, ensuring developers can still meet high-end market demands while retaining the cost and time benefits.

B. Higher Standards and Code Compliance

Modular buildings must meet the same, or often stricter, local, state, and national building codes as traditional structures.

Because they are constructed under controlled conditions and inspected at various stages within the factory before being shipped, their compliance is often easier to guarantee and verify, avoiding costly delays or rework caused by failed on-site inspections.

Conclusion

Modular construction is no longer a niche alternative; it is a mature, technologically-driven process that is fundamentally changing the financial landscape of property development.

By mastering the art of off-site production, the industry is delivering buildings faster, to a higher standard of quality, and, critically, at a lower overall project cost.

The substantial and quantifiable cost savings derived from bulk procurement, labor efficiency, waste reduction, and schedule certainty combine to make a compelling financial case.

The long-term benefits—superior energy performance, enhanced durability, and unparalleled flexibility for expansion or relocation—secure the building’s asset value and reduce operational expenditures for decades.

For developers and investors seeking to maximize their Return on Investment (ROI) while minimizing risk exposure in a volatile market, embracing modular construction is the clear, intelligent path forward.

This methodology represents an investment not just in a building, but in a predictable, profitable, and sustainable future for the construction industry. The successful players in the property space will be those who leverage this innovative approach to unlock true efficiency and financial predictability, leaving behind the expensive uncertainties of traditional site-built methods.