The construction industry, often seen as traditional and slow to innovate, is undergoing a profound transformation. At the vanguard of this revolution is modular construction, an advanced method where buildings are constructed off-site in controlled factory conditions, then transported and assembled on-site. Far from merely prefabrication, modular construction represents a sophisticated, integrated approach that promises to deliver projects with unprecedented speed, efficiency, quality, and sustainability. It’s not just about building differently; it’s about building smarter, faster, and more responsibly, ultimately shaping the blueprint for a quicker, more efficient future in the built environment.

The Evolution of Building: From Traditional to Modular

To truly grasp the significance and advantages of modular construction, it’s essential to understand its place in the historical evolution of building practices and the challenges it seeks to overcome from conventional methods.

A. The Enduring Challenges of Traditional On-Site Construction

For centuries, the dominant method of construction has been largely on-site (stick-built) construction. This involves assembling buildings piece by piece directly at the final location, exposed to the elements and relying heavily on manual labor. While deeply ingrained, this traditional approach is fraught with inefficiencies and limitations in the modern era:

- Extended Timelines and Delays: On-site construction is notoriously time-consuming. Projects are often subjected to unpredictable delays caused by adverse weather conditions, labor shortages, material delivery issues, and unforeseen site complications. These delays lead to increased costs and postponed project completion.

- High Labor Dependency and Skill Shortages: Traditional construction is heavily reliant on a large, skilled labor force working on-site. The global construction industry increasingly faces a severe shortage of skilled tradespeople, driving up labor costs and impacting project schedules. Manual processes also introduce higher risks of human error and safety incidents.

- Variable Quality Control: Quality can be inconsistent in traditional builds due to varying skill levels of on-site workers, exposure to harsh weather, and the inherent challenges of managing numerous subcontractors. Quality checks are often reactive, identifying issues after they occur, leading to costly rework.

- Environmental Impact: On-site construction typically generates substantial waste, with materials often cut to size on-site, leading to offcuts and debris. Construction sites also contribute to noise pollution, dust, and traffic congestion in surrounding areas.

- Cost Overruns: Unpredictable factors like weather delays, material price fluctuations, labor inefficiencies, and rework due to quality issues frequently lead to projects exceeding their initial budget estimates, making financial planning difficult.

- Safety Concerns: Construction sites are inherently hazardous environments. The presence of heavy machinery, working at heights, and exposure to various risks contribute to a higher rate of accidents and injuries compared to controlled factory settings.

B. The Principles of Modular Construction: A New Era

Modular construction represents a sophisticated evolution, moving a significant portion of the building process into controlled, off-site environments. It’s a method where entire building sections, or ‘modules,’ are fabricated in a factory, complete with plumbing, electrical, and interior finishes, before being transported to the final site for assembly.

- Factory-Controlled Environment: Modules are built in state-of-the-art manufacturing facilities, protected from weather elements. This controlled environment ensures consistent quality, optimized production lines, and adherence to precise specifications.

- Parallel Processes: Unlike traditional construction where foundations must be completed before vertical construction begins, modular construction allows site work (foundation, utilities) and module fabrication to occur simultaneously. This parallelization dramatically reduces overall project timelines.

- Assembly-Line Efficiency: Modular factories often utilize assembly-line techniques, akin to automotive manufacturing, optimizing workflows, material handling, and labor utilization. This leads to greater efficiency and predictability in production.

- Integrated Building Information Modeling (BIM): Modular construction relies heavily on advanced digital tools like BIM from the design phase through manufacturing and assembly. BIM enables precise planning, clash detection, and better coordination across all project stakeholders.

- Just-in-Time (JIT) Delivery: Modules are manufactured and delivered to the site precisely when needed, minimizing on-site storage requirements, reducing congestion, and optimizing logistics.

- Reduced On-Site Disruption: With most of the work done off-site, the actual time spent on the construction site is significantly reduced. This minimizes noise, dust, traffic, and overall disruption to surrounding communities.

This strategic shift from sequential on-site processes to parallel, factory-based manufacturing fundamentally reshapes how buildings are delivered, promising a future of faster, more efficient, and higher-quality construction.

Core Principles and Defining Characteristics of Modular Construction

Modular construction is distinguished by several core principles and characteristics that collectively define this innovative building method and set it apart from traditional approaches or even simple prefabrication

A. Off-Site Manufacturing (OSM)

The most defining characteristic is the extensive use of Off-Site Manufacturing (OSM). Instead of being built from scratch on the final site, significant portions of the building, often complete with internal finishes, plumbing, and electrical systems, are manufactured in a specialized factory setting. This process allows for:

- Controlled Environment: Protection from adverse weather conditions (rain, extreme temperatures) that typically cause delays and impact material quality in traditional construction.

- Optimized Workflow: Factory environments can be optimized for efficiency, often employing assembly-line techniques, specialized machinery, and consistent production schedules, leading to higher output and reduced waste.

- Consistent Quality: Standardized processes and a controlled environment enable much tighter quality control, ensuring modules meet precise specifications and reducing defects.

B. Unitized/Volumetric Modules

Modular construction primarily focuses on creating unitized or volumetric modules. These are three-dimensional sections of a building (e.g., entire rooms, apartment units, hospital wings, hotel rooms) that are fully finished internally, structurally complete, and ready for integration. This contrasts with 2D panelized systems, offering a higher degree of completeness off-site.

C. Parallel Construction Processes

A key efficiency gain comes from parallel construction processes. In traditional building, site preparation (foundations, utilities) must be completed before vertical construction can begin. With modular construction, modules are fabricated in the factory simultaneously while site work is underway. This parallelism can significantly reduce the overall project schedule.

D. Transportation and Assembly

Once completed in the factory, modules are meticulously transported to the final construction site. The on-site phase then primarily involves assembly – lifting and placing modules onto the foundation and connecting them to form the complete building. This assembly phase is typically much faster and less disruptive than traditional construction.

E. Design for Manufacturing and Assembly (DfMA)

Modular construction heavily relies on Design for Manufacturing and and Assembly (DfMA) principles. This means that the design process explicitly considers how components will be fabricated in the factory and how they will be assembled on-site. Designs are often standardized and optimized for repeatable production, reducing complexity and potential errors during manufacturing and installation.

F. Enhanced Quality Control and Inspection

The factory environment allows for rigorous and systematic quality control and inspection at every stage of module fabrication. Unlike scattered on-site inspections, factory checks are more centralized, consistent, and easier to perform, leading to higher overall build quality and fewer defects by the time modules reach the site.

G. Reduced On-Site Waste and Environmental Impact

Because materials are precisely cut and managed in a factory, waste generation is significantly reduced compared to traditional construction. Factory environments also allow for better recycling of excess materials. Furthermore, reduced on-site activity translates to less noise pollution, dust, and traffic congestion, minimizing the overall environmental footprint and disruption to surrounding communities.

H. Digital Integration (BIM and Digital Twins)

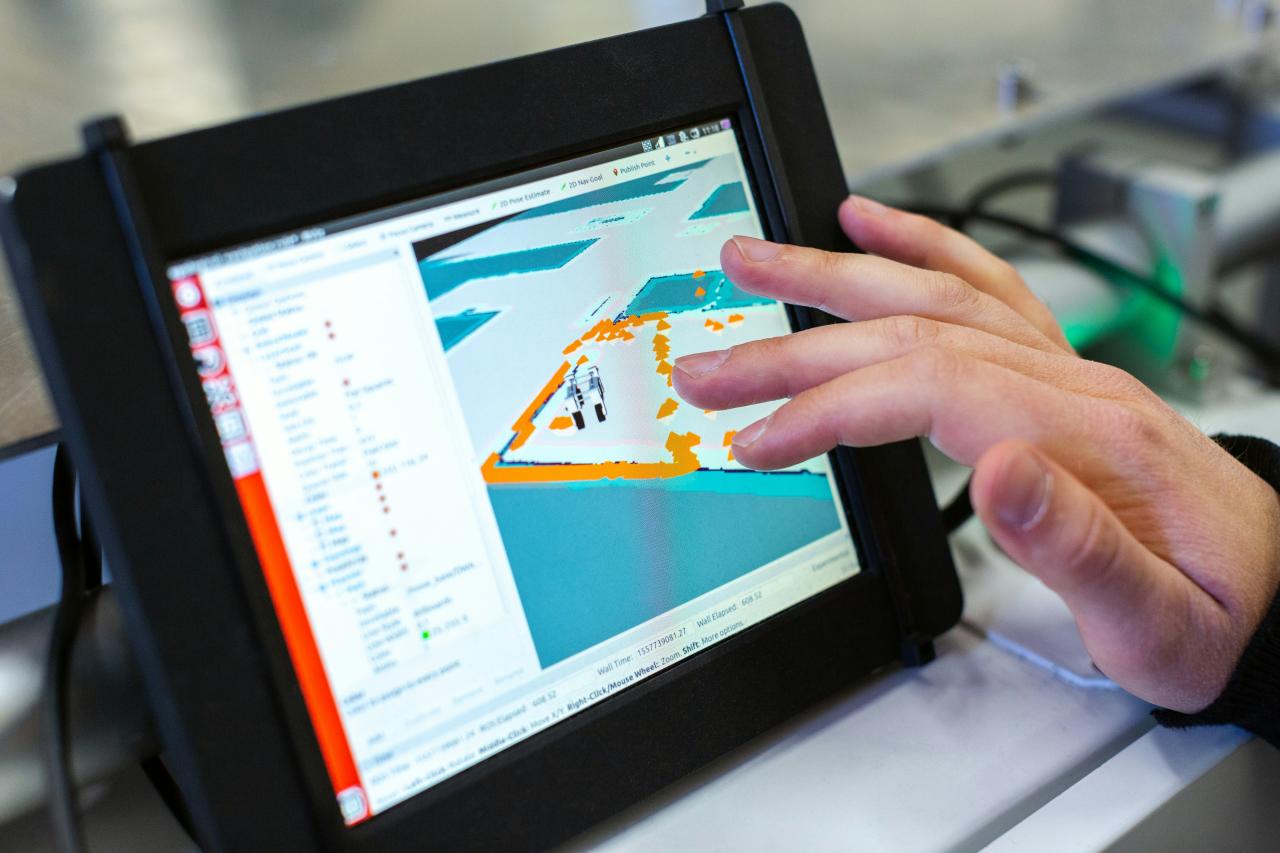

Modular construction leverages advanced digital tools. Building Information Modeling (BIM) is central to the design, planning, and coordination of modular projects, enabling precise component fabrication and clash detection. The concept of Digital Twins (virtual replicas of physical buildings) can also be extended to modular projects, aiding in lifecycle management and predictive maintenance.

Unlocking the Strategic Advantages of Modular Construction

The adoption of modular construction offers a compelling array of benefits that directly address many of the chronic limitations inherent in traditional building methods, empowering developers, builders, and clients to achieve greater operational excellence and project success.

A. Dramatically Accelerated Project Timelines

One of the most immediate and impactful benefits of modular construction is the significantly reduced project timeline. By enabling parallel processes – site preparation and foundation work occurring concurrently with module fabrication in the factory – the overall construction schedule can be compressed by 30-50% compared to traditional methods. This accelerated delivery translates directly into earlier revenue generation for commercial projects, faster occupancy for residential buildings, and quicker realization of project goals, providing a crucial competitive advantage in fast-paced markets.

B. Enhanced Quality Control and Predictability

The controlled environment of a factory setting is paramount for ensuring superior quality control and predictability. Unlike open construction sites exposed to weather and varying skill levels, factory production allows for standardized processes, precise tolerances, and consistent application of quality checks at every stage. This results in higher-quality modules with fewer defects, reducing the need for costly rework and ensuring the final building meets or exceeds design specifications, leading to greater client satisfaction and long-term durability.

C. Optimized Cost Efficiency

While the initial unit cost of a module might sometimes appear comparable to traditional build, modular construction offers substantial cost efficiencies when considering the total project lifecycle. These savings stem from:

- Reduced Labor Costs: Less reliance on fluctuating on-site labor and more efficient use of a stable, factory-based workforce.

- Minimized Waste: Factory environments enable precise material management and recycling, leading to less material waste.

- Faster Completion: Accelerated timelines mean reduced financing costs (interest on loans) and earlier revenue streams.

- Predictable Budgeting: Less exposure to weather delays, theft, and on-site errors leads to more accurate project budgeting and fewer cost overruns.

- Reduced Site Management: Less time on-site means reduced overhead for site supervision, security, and temporary facilities.

D. Improved Safety Records

Construction sites are inherently hazardous. Modular construction drastically improves worker safety by shifting the majority of the work into a controlled factory environment. Workers operate in ergonomically designed workstations, away from heavy machinery and dangerous heights. This controlled setting leads to fewer accidents, injuries, and health risks, creating a safer work environment for the construction workforce and reducing liability for companies.

E. Enhanced Environmental Sustainability

Modular construction inherently boasts superior environmental sustainability credentials. The factory setting allows for precise material cutting and management, significantly reducing material waste compared to on-site construction. Waste materials can be more easily recycled or repurposed within the factory. Furthermore, reduced on-site activity means less noise pollution, dust, and vehicle emissions from transportation, contributing to a smaller carbon footprint and minimizing disruption to surrounding communities. The potential for higher energy efficiency in modular buildings is also a factor.

F. Greater Site Flexibility and Reduced Disruption

With significant work performed off-site, the actual time spent on the construction site is dramatically minimized. This leads to greater site flexibility as assembly can happen rapidly, and significantly reduced disruption to adjacent businesses, residents, and traffic flow. This benefit is particularly valuable for projects in dense urban areas, sensitive environments, or operational facilities (like hospitals) where minimizing impact is critical.

G. Potential for Design Customization and Adaptability

While often associated with standardization, modern modular construction can offer a surprising degree of design customization and adaptability. Advanced manufacturing techniques and Building Information Modeling (BIM) allow for variations in module design. Furthermore, modular buildings can be more easily expanded, reconfigured, or even relocated in the future, providing inherent adaptability for evolving needs (e.g., temporary housing, pop-up retail, rapidly deployable healthcare facilities).

H. Overcoming Labor Shortages and Skill Gaps

The factory environment allows for a more stable and controlled workforce, providing opportunities for training and upskilling. This helps in overcoming industry-wide labor shortages and skill gaps by enabling a more industrialized and less physically demanding form of construction. It also attracts a new generation of workers interested in technology-driven manufacturing.

Navigating the Challenges of Modular Construction Adoption

Despite its compelling advantages, the widespread adoption of modular construction faces several challenges that organizations and the industry must collaboratively address.

A. Perceptions and Industry Resistance

One of the significant hurdles is overcoming historical perceptions and ingrained industry resistance. Traditional builders, architects, and clients may view modular construction as synonymous with temporary structures or low-quality prefabricated housing, rather than high-quality, permanent buildings. Educating the market and shifting this perception requires demonstrating successful, high-profile modular projects and highlighting quality assurance processes.

B. Transportation and Logistics Complexities

Transporting large, three-dimensional modules from the factory to the construction site presents unique transportation and logistics complexities. This involves managing oversized loads, navigating narrow roads, securing necessary permits, and often coordinating police escorts. These challenges can be exacerbated by geographical distances between the factory and the site, adding to costs and planning efforts.

C. Financing and Insurance Hurdles

The project financing model for modular construction differs from traditional methods. Banks and lenders are accustomed to incremental payments tied to on-site progress. With modular, a significant portion of the cost is incurred upfront during factory fabrication, often before any work begins on-site. This can create financing and insurance hurdles as traditional models may not fully account for the value of off-site manufactured assets, requiring new financial instruments and understanding.

D. Design Coordination and Early Decisions

Modular construction demands a higher level of design coordination and early decision-making. Changes made late in the design phase or during fabrication can be extremely costly and disruptive, as modules are being built in a standardized, assembly-line fashion. This requires greater upfront precision in design and closer collaboration between architects, engineers, and manufacturers from the very beginning of the project.

E. Regulatory and Permitting Frameworks

Building codes and permitting processes are often tailored for traditional on-site construction and can be cumbersome for modular projects. Navigating disparate local, state, and national regulations, especially regarding off-site inspections and inter-state module transportation, can create significant regulatory and permitting hurdles. Advocating for updated, more modular-friendly regulatory frameworks is essential for wider adoption.

F. Limited Factory Capacity and Geographic Reach

While the modular industry is growing, the current number of advanced modular manufacturing facilities, particularly those capable of producing highly complex buildings, is still limited. This can lead to limited factory capacity and geographic reach, meaning projects might need to source modules from distant factories, increasing transportation costs and lead times. Investment in more regional factories is needed to scale the industry.

G. Integration with On-Site Elements

Even in highly modular projects, there’s always some degree of on-site work required, particularly for foundations, utilities, landscaping, and often roofing or facade elements that connect multiple modules. Seamless integration with on-site elements requires meticulous planning and coordination to ensure perfect alignment and weatherproofing, as minor discrepancies can lead to significant problems.

H. Workforce Training and Skill Gaps

While modular construction helps address some labor shortages, it also requires a different skill set. Workers need to be proficient in factory-based manufacturing, digital design tools, and precision assembly. There’s a need for workforce training programs to upskill traditional construction workers or train new talent for this industrialized approach to building.

Best Practices for Successful Modular Construction Implementation

To maximize the benefits of modular construction and effectively mitigate its inherent complexities, organizations should rigorously adhere to a set of proven best practices. These guidelines are crucial for designing, managing, and delivering successful modular projects.

A. Prioritize Early Design Collaboration and Integration

Success in modular construction hinges on early design collaboration and integration. Bring together all key stakeholders—client, architect, engineers, and modular manufacturer—from the project’s inception. Utilize Building Information Modeling (BIM) as a central platform for design, coordination, and clash detection. This upfront effort ensures the design is optimized for manufacturing and assembly (DfMA) and minimizes costly changes later in the process.

B. Select the Right Projects and Partners

Not every project is ideally suited for modular construction. Identify projects that benefit most from its advantages (e.g., repetitive units like hotels, apartments, healthcare facilities, schools, or projects with tight schedules/site constraints). Crucially, select experienced modular manufacturers and partners who have a proven track record, understand the nuances of the process, and can collaborate effectively from design to delivery.

C. Standardize and Optimize Module Designs

While customization is possible, maximizing the benefits of modular construction often involves standardizing and optimizing module designs. Develop a library of reusable module types where feasible. This standardization leads to greater manufacturing efficiency, reduced costs per unit, and higher quality through repeated production. Even with standardization, variations in finishes and external cladding can offer architectural diversity.

D. Implement Robust Logistics and Transportation Planning

Given the complexities of transporting large modules, develop a robust logistics and transportation plan early in the project. This includes detailed route surveys, securing necessary permits for oversized loads, coordinating specialized transportation equipment, and planning for just-in-time delivery to minimize on-site storage and congestion. Accurate scheduling is paramount to avoid delays during assembly.

E. Align Financing and Legal Frameworks

Address financing and legal frameworks early on. Educate lenders and insurers about the modular construction process, particularly the upfront payment for off-site fabrication. Work with legal counsel to draft contracts that appropriately manage risks, define payment milestones, and clearly delineate responsibilities between the client, general contractor, and modular manufacturer for both off-site and on-site work.

F. Invest in Digital Tools and Automation

Leverage advanced digital tools and automation throughout the modular workflow. This includes sophisticated BIM software for design and coordination, manufacturing execution systems (MES) for factory production control, and potentially robotics or automated machinery in the factory. Digital twins can extend these benefits into operations and maintenance.

G. Develop Comprehensive Quality Assurance Processes

Implement comprehensive quality assurance (QA) processes at every stage of the modular process, both in the factory and on-site. This includes rigorous material inspections, in-process checks during fabrication, complete module inspections before transport, and final assembly quality checks. Leverage digital tools for tracking quality data and ensure clear handover procedures for each completed module.

H. Manage On-Site Integration Meticulously

Despite off-site work, the on-site integration phase is critical. Meticulous planning and execution are required for foundations, utility hook-ups, inter-module connections, and any site-specific facade or roofing elements. Ensure precise surveying, accurate leveling, and highly skilled on-site teams for the final assembly to ensure structural integrity, weatherproofing, and seamless aesthetic integration.

I. Prioritize Safety and Workforce Training

Continue to prioritize safety not just in the factory but also during transport and on-site assembly. Develop specific safety protocols for lifting and connecting modules. Invest in workforce training programs that equip workers with the new skills required for advanced manufacturing, digital tool usage, and the specialized on-site assembly techniques involved in modular construction.

J. Foster a Culture of Innovation and Collaboration

Successful modular adoption requires a shift in mindset and a culture of innovation and collaboration. Encourage open communication, shared problem-solving, and a willingness to adapt traditional processes. Embrace continuous improvement, learning from each project to refine modular workflows and leverage new technologies as they emerge.

The Future Trajectory of Modular Construction

The modular construction industry is poised for significant growth and continued innovation, driven by technological advancements, evolving market demands, and a growing recognition of its benefits. Several key trends are shaping its future trajectory.

A. Increased Automation and Robotics in Factories

The future of modular construction factories will see a dramatic increase in automation and robotics. Automated systems will handle repetitive tasks like cutting, welding, and assembly, improving precision, speed, and safety while reducing labor costs. Robots will assist human workers, particularly for heavy lifting and dangerous tasks, leading to highly efficient and lights-out manufacturing environments for building components.

B. AI and Generative Design Integration

Artificial intelligence (AI) will play a transformative role, particularly in the design phase. AI-powered generative design tools will rapidly explore countless design variations, optimizing for factors like structural integrity, material efficiency, energy performance, and cost, specifically tailored for modular fabrication. AI can also optimize factory layouts, production schedules, and logistics.

C. Enhanced Material Innovation

Expect to see continued advancements in material innovation specifically for modular applications. This includes lighter yet stronger composite materials, self-healing concrete, advanced insulation systems, and smart materials integrated directly into modules. Sustainable and recyclable materials will be prioritized, further enhancing the environmental benefits of modular construction.

D. Digital Twins and Lifecycle Management

The concept of Digital Twins will become integral to modular construction. Virtual replicas of modular buildings, created during the design and fabrication phases, will be maintained throughout the building’s lifecycle. These digital twins will collect real-time data from sensors (e.g., energy consumption, structural performance), enabling predictive maintenance, optimized operations, and smarter building management for owners and facilities managers.

E. Mass Customization and Personalization

While standardization drives efficiency, the future will allow for greater mass customization and personalization within modular frameworks. Advanced manufacturing techniques, coupled with AI and flexible production lines, will enable architects and clients to specify unique designs and finishes for modular units without significantly increasing costs or production times, moving beyond a ‘one-size-fits-all’ approach.

F. Integration with Off-Site Construction Ecosystems

The modular industry will increasingly integrate with a broader off-site construction ecosystem. This includes tighter collaboration with suppliers of highly engineered components (e.g., prefabricated MEP systems, bathroom pods), specialized logistics providers, and digital platforms that connect clients, designers, and manufacturers, fostering a more interconnected and efficient building supply chain.

G. Sustainable and Net-Zero Energy Modular Buildings

With growing environmental concerns, the focus on building sustainable and net-zero energy modular buildings will intensify. Factories will optimize for minimal waste, maximum recycling, and renewable energy use in production. Modular designs will integrate advanced energy-efficient systems, renewable energy sources (solar panels), and smart building technologies to minimize operational carbon footprints.

H. Modular Solutions for Disaster Recovery and Humanitarian Aid

The speed and deployability of modular construction make it an ideal solution for rapid disaster recovery and humanitarian aid. Future modular units will be designed for quick deployment in crisis zones, providing essential housing, medical facilities, and community infrastructure with unprecedented speed and efficiency after natural disasters or in humanitarian crises.

Conclusion

Modular construction is far more than a passing trend; it is a transformative force poised to redefine the global construction industry. By shifting the bulk of the building process into controlled, high-tech factory environments, it addresses many of the enduring challenges of traditional on-site methods, offering unparalleled advantages in speed, quality, cost efficiency, and safety. Moreover, its inherent lean manufacturing principles align perfectly with the pressing need for greater environmental sustainability in the built environment.

While challenges remain—from overcoming entrenched perceptions to navigating complex logistics and evolving regulatory frameworks—the industry is actively addressing these hurdles through technological innovation, increased investment, and collaborative partnerships. As automation, AI, and advanced materials become more integrated, modular construction will not only build faster but also smarter, more sustainably, and with greater precision. For stakeholders across the construction value chain, embracing modular methods is no longer just an option but a strategic imperative to build the adaptable, resilient, and efficient infrastructure required for a rapidly evolving future. Modular construction is truly the blueprint for building tomorrow’s world, today.