In the dynamic and ever-evolving world of architecture, engineering, and construction, a paradigm shift is quietly but powerfully underway. For centuries, the default approach to building has been anchored in solidity, mass, and unyielding strength, often equating robustness with sheer weight and volume. However, as global demands for sustainability, efficiency, and adaptability intensify, this traditional mindset is being challenged by a groundbreaking movement: the Lightweight Structures Revolutionize Building. This innovative approach embraces principles of minimal material usage, optimized form, and advanced material science to create structures that are not only lighter but also stronger, more sustainable, and astonishingly versatile.

The conventional wisdom of “heavier is stronger” is giving way to a more sophisticated understanding of structural integrity, where intelligence of design and material properties outweigh brute force. This revolution is driven by urgent global challenges: the need to reduce carbon footprints, mitigate the environmental impact of construction, build rapidly in response to urban growth and disaster, and create adaptable spaces that can evolve with changing human needs. Lightweight structures offer compelling answers to these complex problems, pushing the boundaries of what is aesthetically possible and environmentally responsible.

This comprehensive guide will delve deep into the multifaceted aspects of how Lightweight Structures Revolutionize Building, exploring the scientific principles that underpin their strength, detailing the groundbreaking materials and construction techniques driving their adoption, and illustrating their wide-ranging applications across various sectors. We will cover everything from the historical roots of lightweight design to future trends in smart materials and adaptive architecture. By the end of this article, you will possess the insights and practical knowledge to systematically understand the profound impact of this revolution, transforming your perception of what is possible in the built environment and inspiring a new era of elegant, efficient, and sustainable construction.

Why Lightweight is the Future

Understanding the driving forces behind the Lightweight Structures Revolutionize Building is crucial for grasping its significance.

A. Environmental Imperatives

- A. Reduced Material Consumption: Lighter structures inherently require less raw material, leading to reduced mining, extraction, and processing impacts.

- B. Lower Embodied Carbon: Less material means a smaller carbon footprint associated with manufacturing, transportation, and construction processes.

- C. Energy Efficiency: Lighter components are easier to transport and install, reducing fuel consumption and associated emissions during the construction phase.

- D. Sustainable Lifecycles: Many lightweight materials are recyclable, reusable, or have longer lifespans, contributing to circular economy principles.

B. Economic Advantages

- A. Lower Material Costs: Directly related to reduced material consumption, often leading to significant savings in procurement.

- B. Faster Construction Times: Prefabricated lightweight components can be assembled rapidly off-site or on-site, drastically cutting project schedules and labor costs.

- C. Reduced Foundation Requirements: Lighter overall building weight means less stress on foundations, potentially allowing for simpler, less expensive substructures.

- D. Logistical Efficiencies: Easier transportation, smaller cranes, and less on-site storage needed for lighter components.

C. Performance and Adaptability Benefits

- A. Increased Span Capabilities: Lightweight materials with high strength-to-weight ratios allow for longer spans without intermediate supports, creating open, flexible spaces.

- B. Enhanced Seismic Performance: Lighter buildings experience less inertial force during earthquakes, making them inherently more resistant to seismic activity.

- C. Flexibility and Adaptability: Many lightweight systems are modular and demountable, allowing structures to be easily reconfigured, expanded, or even relocated.

- D. Aesthetic Freedom: The ability to create soaring, ethereal, or organic forms that would be impractical or impossible with traditional heavy construction.

- E. Thermal Performance: Advanced lightweight materials can often integrate high levels of insulation, contributing to superior thermal efficiency.

The Core of Lightweight Design

The innovation in lightweight structures is intrinsically linked to advancements in material science.

A. Advanced Composites

These are engineered materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or microscopic level within the finished structure.

- A. Carbon Fiber Reinforced Polymers (CFRP): Extremely high strength-to-weight ratio, excellent stiffness. Used in high-performance structures, bridges, and architectural features where strength is paramount.

- B. Glass Fiber Reinforced Polymers (GFRP): More cost-effective than CFRP, good strength, and corrosion resistance. Used for facades, panels, and structural elements.

- C. Fiber-Reinforced Concrete (FRC): Incorporates synthetic or natural fibers into concrete to improve tensile strength, ductility, and crack resistance, allowing for thinner, lighter concrete elements.

B. High-Performance Metals

Beyond traditional steel, new alloys and forms are emerging.

- A. High-Strength Steel Alloys: Lighter gauges of steel with superior tensile strength allow for leaner structural members while maintaining load-bearing capacity.

- B. Aluminum Alloys: Exceptionally light and corrosion-resistant. Used for cladding, curtain walls, roof structures, and increasingly, primary structural frames.

C. Engineered Wood Products

Modern wood technology has pushed the boundaries of timber construction.

- A. Cross-Laminated Timber (CLT): Layers of timber glued perpendicular to each other, creating incredibly strong, stable, and lightweight panels for walls, floors, and roofs. Allows for multi-story timber buildings.

- B. Glued Laminated Timber (Glulam): Individual laminations of timber bonded together to form large, strong structural members, enabling long spans and complex curves.

- C. Laminated Veneer Lumber (LVL): Similar to plywood but with veneers oriented in the same direction, creating high-strength, dimensionally stable beams and headers.

D. Technical Textiles and Membranes

Flexible materials that create vast, lightweight enclosures.

- A. ETFE (Ethylene Tetrafluoroethylene) Films: Highly transparent, lightweight, and durable polymer film. Used as a replacement for glass in large-span roofs and facades (e.g., Allianz Arena, Beijing National Aquatics Center), offering excellent thermal performance and light transmission.

- B. PTFE (Polytetrafluoroethylene) Coated Fiberglass: Strong, durable, and weather-resistant fabric used for tensioned membrane structures (e.g., airport terminals, sports stadia).

- C. PVC-Coated Polyester: More economical than PTFE, suitable for smaller-scale temporary or permanent tensile structures.

E. Cellular and Foam Materials

Lightweight options for insulation and structural fill.

- A. Aerogels: Extremely low-density synthetic porous material derived from a gel. Excellent thermal insulators, finding applications in high-performance building envelopes.

- B. Foam Glass / Foam Concrete: Lightweight, insulating materials used for fill, blocks, or panels, reducing dead load and improving thermal performance.

Structural Systems Redefined

The revolution isn’t just about materials; it’s about how these materials are configured into innovative structural systems.

A. Tensile Structures and Cable Nets

Utilize flexible elements (cables, membranes) primarily in tension, creating lightweight and visually dramatic forms.

- A. Membrane Structures: Large, fabric-like surfaces supported by tensioned cables and masts, often seen in large-span roofs (e.g., sports arenas, exhibition halls).

- B. Cable-Net Facades: Glass panels supported by a delicate grid of tensioned cables, providing transparency with minimal visible structure.

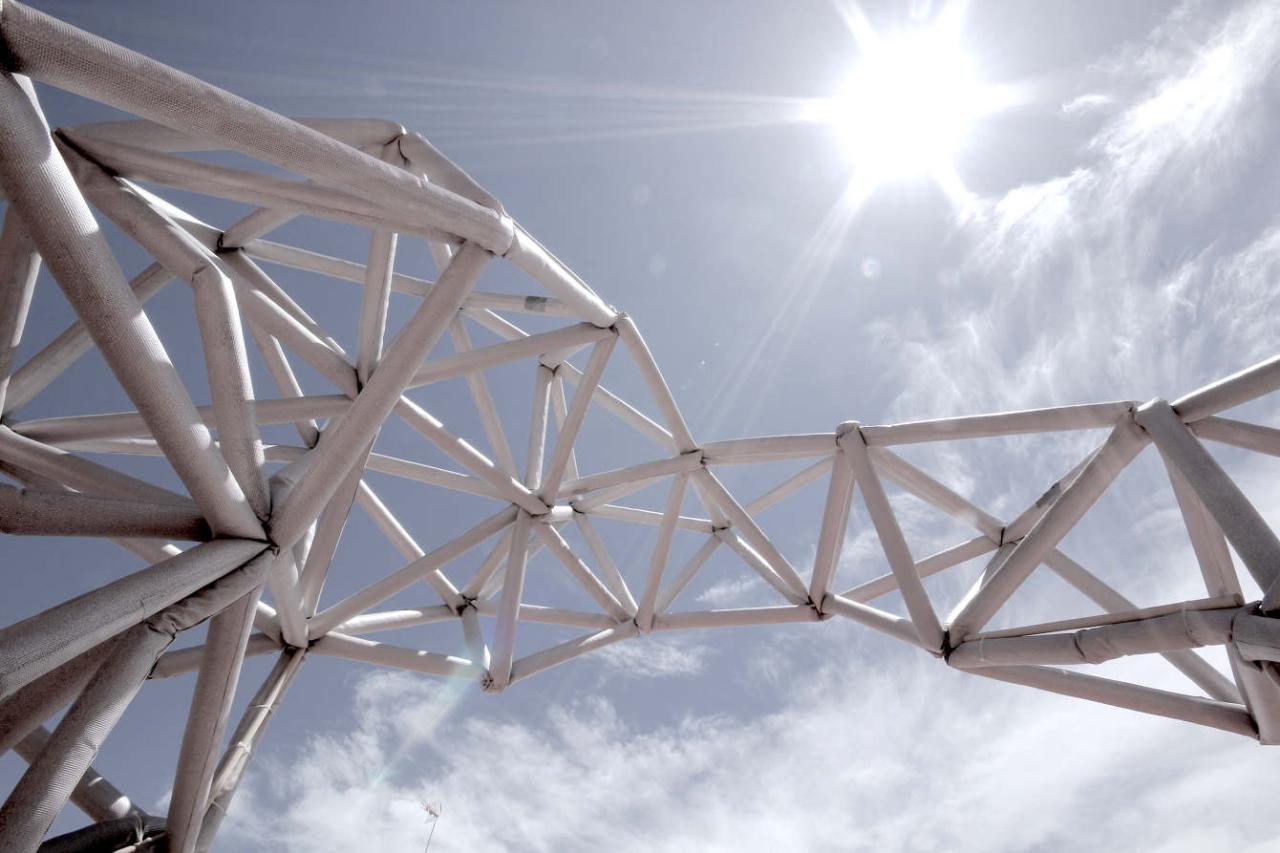

B. Space Frames and Gridshells

Highly efficient 3D lattice structures that distribute loads effectively.

- A. Space Frames: Modular systems of interconnected linear elements forming stable three-dimensional frameworks, ideal for large-span roofs with minimal weight.

- B. Gridshells: Double-curved lattice structures where members are initially straight and bent into form on-site, creating elegant and efficient enclosures (e.g., Mannheim Multihalle).

C. Modular and Prefabricated Systems

Construction techniques that leverage lightweight components for speed and efficiency.

- A. Volumetric Modules: Entire rooms or sections of a building fabricated off-site and assembled on-site, drastically reducing construction time and waste.

- B. Panelized Systems: Walls, floors, and roof elements manufactured as large panels off-site and assembled on-site.

- C. Flat-Pack Structures: Components designed for easy transport and rapid assembly, often seen in temporary or emergency housing.

D. Pneumatic Structures (Air-Supported/Air-Inflated)

Structures stabilized by internal air pressure.

- A. Air-Supported Structures: A single membrane held up by internal air pressure greater than external atmospheric pressure (e.g., temporary sports domes).

- B. Air-Inflated Structures: Double-layer membranes creating structural tubes or elements that are inflated to create a rigid form (e.g., inflatable buildings, architectural features).

E. Hybrid Lightweight Systems

Combining different lightweight materials and structural principles to optimize performance.

- A. Steel-Timber Hybrids: Using the tensile strength of steel with the sustainable and compressive strength of mass timber.

- B. Composite Beams/Panels: Integrating different materials (e.g., foam core with composite skins) to achieve specific thermal, structural, and weight characteristics.

The Broad Reach of Lightweight Structures

The implications of this revolution extend far beyond construction sites, shaping our cities and future.

A. Urban Resilience and Disaster Response

Lightweight, rapidly deployable structures are crucial for post-disaster housing, medical facilities, and infrastructure, offering speed and flexibility. They also improve seismic resilience in high-risk areas.

B. Sustainable Development and Circular Economy

The focus on reduced material use, recyclability, and adaptable designs aligns perfectly with global sustainability goals, driving down embodied energy and waste.

C. Architectural Aesthetics and Design Freedom

The ability to create large, column-free spaces, transparent envelopes, and dynamic forms allows architects unprecedented freedom, leading to more iconic and functional buildings.

D. Affordable and Rapid Housing Solutions

Modular and prefabricated lightweight construction offers potential for faster, more cost-effective housing, addressing global housing shortages.

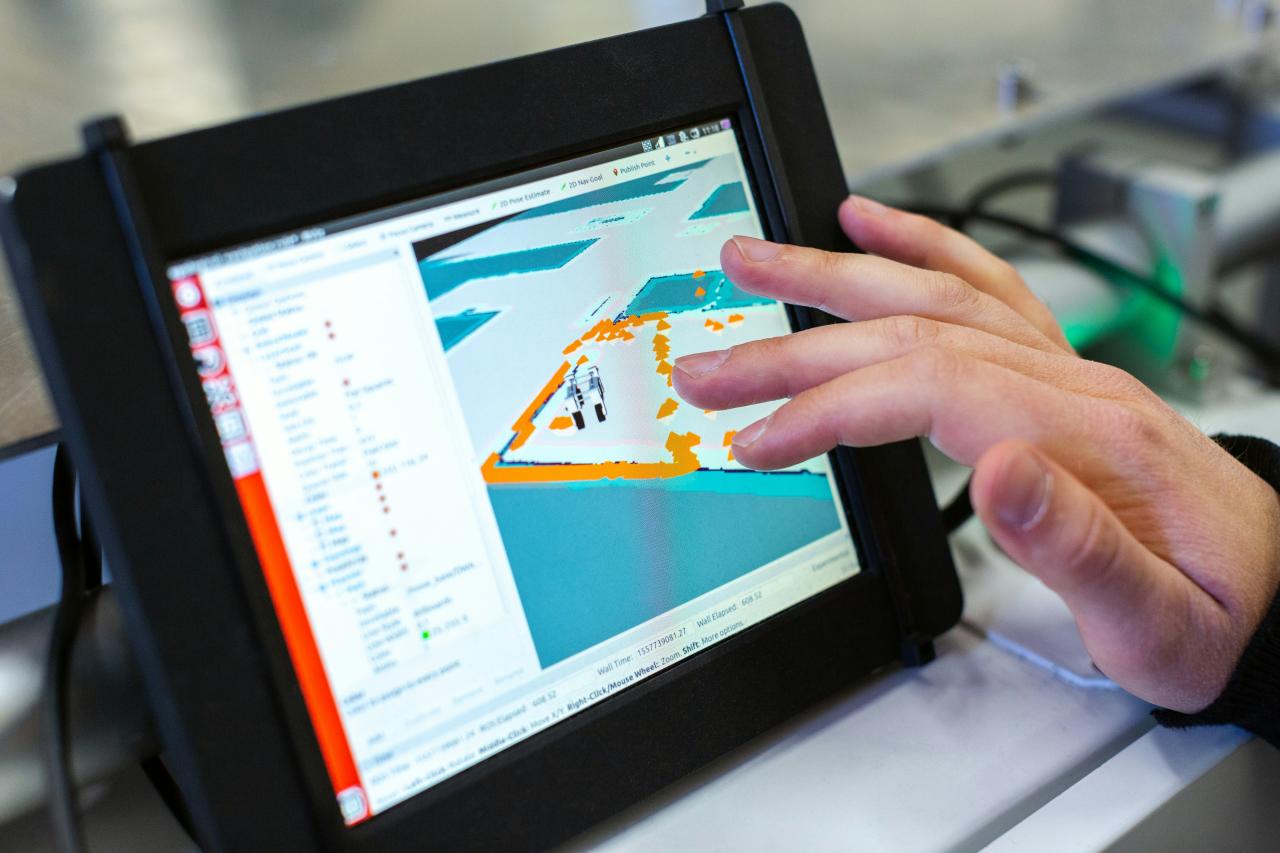

E. Smart and Adaptive Structures

Future lightweight structures will increasingly integrate sensors, AI, and responsive materials to adapt to environmental conditions, user needs, and even self-repair. Examples include facades that adjust transparency or structures that monitor their own structural health.

F. Space Architecture and Exploration

The principles of lightweight, deployable structures are critical for building habitats and infrastructure in space, where every gram counts.

Conclusion

The Lightweight Structures Revolutionize Building is far more than a mere shift in construction techniques; it represents a fundamental re-imagining of how we conceive, design, and construct our built environment. This guide has illuminated the profound truth that true strength and resilience in the 21st century are no longer synonymous with brute mass, but with the intelligent optimization of form, the strategic application of advanced materials, and an unwavering commitment to efficiency and sustainability. By systematically embracing this revolution, we are not merely building structures; we are crafting an elegant, responsive, and responsible future.

By understanding the compelling environmental, economic, and performance imperatives driving this paradigm shift—from drastically reducing embodied carbon and accelerating construction timelines to enhancing seismic resilience and unleashing unprecedented aesthetic freedom—we grasp the true significance of this movement. The strategic adoption of groundbreaking materials such as advanced composites, high-performance metals, engineered wood products, and technical textiles, coupled with innovative structural systems like tensile membranes, space frames, and modular construction, transforms our capabilities. This proactive approach empowers engineers and architects to transcend traditional limitations, creating structures that are lighter on the planet, lighter on budgets, and lighter in spirit.

The profound impact of this revolution permeates every facet of our built world: more sustainable cities with reduced ecological footprints, more resilient communities better prepared for natural challenges, more adaptable spaces that evolve with human needs, and more aesthetically inspiring architecture that pushes the boundaries of imagination. Ultimately, by mastering the principles and embracing the tools of the Lightweight Structures Revolution, we are not just optimizing construction; we are actively investing in a future where elegance, efficiency, and environmental stewardship are intrinsically intertwined, leading to a built environment that is not only robust and functional but also profoundly harmonious with the natural world and the aspirations of humanity.