In the ever-evolving domain of structural engineering, an exciting transformation is underway. Advanced artificial intelligence (AI) technologies are now integral to planning and designing structures—bringing enhanced accuracy, streamlined processes, and high-efficiency outcomes. This article delves into how AI optimizes structural engineering plans, elaborates on key methodologies, outlines benefits and challenges, and offers practical guidance for professionals seeking to deploy AI-driven workflows.

Introduction

Structural engineering has traditionally relied on human expertise, manual calculations, and rule-based design. Engineers analyze loads, materials, geometry, and codes to produce safe and resilient structures. However, as structures become more complex and multidisciplinary requirements intensify—covering sustainability, cost efficiency, seismic resilience, and digital modelling—the traditional approach can become time-consuming, error-prone, and resource heavy.

Enter artificial intelligence. By leveraging machine learning (ML), generative design, and optimization algorithms, AI provides structural engineers with tools to explore design alternatives swiftly, simulate behavior accurately, detect issues proactively, and iterate faster. In this context, AI enhances planning of structural systems—from conceptual design to detailed documentation—and supports better decision-making across the project lifecycle.

How AI Transforms Structural Engineering Plans

AI applies to structural engineering planning in several ways:

A. Conceptual Design and Geometry Generation

In early design phases, AI tools can generate structural geometry options based on functional requirements, material choices, site constraints, and performance goals. Instead of manually drawing dozens of variants, engineers can ask AI to propose optimal configurations, thus accelerating ideation and innovation.

B. Performance Simulation and Optimization

Once geometry is established, AI models simulate structural behavior under loads, vibrations, thermal effects, and other environmental factors. Through optimization loops, the AI can adjust member sizes, material grades, and connections to meet performance targets (such as minimizing weight or cost while meeting safety margins).

C. Code Compliance and Automated Checks

Structural designs must comply with building codes and standards (for example, seismic design provisions, fire safety, wind loading). AI systems can be trained on large libraries of codes and past compliance decisions, automatically reviewing design models and flagging non-compliant items, accelerating the review process.

D. Generative Design for Member Sizing and Layout

Generative design, a particular AI approach, explores enormous design spaces. It proposes hundreds or thousands of structural layouts, varying beam locations, column grids, bracing arrangements, and connections. The engineer then selects a solution that best balances performance, constructability, and cost.

E. Clash Detection and Coordination

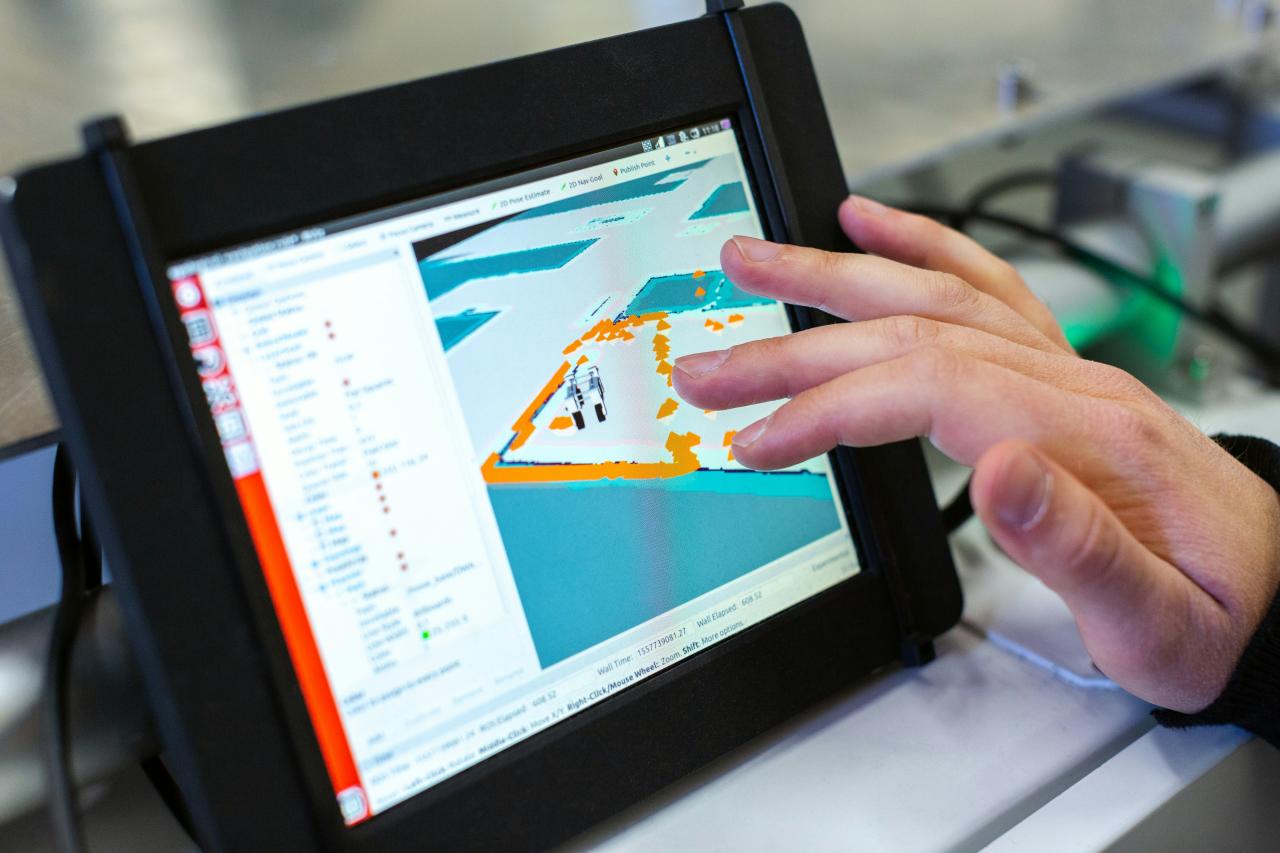

In integrated BIM (Building Information Modelling) environments, AI can detect clashes between structural elements, mechanical, electrical, and plumbing systems. Early detection prevents costly rework later in construction, improving schedule reliability and reducing waste.

F. Predictive Maintenance and Life-Cycle Evaluation

Beyond planning and construction, AI also supports monitoring, maintenance, and life-cycle performance of structures. By analyzing sensor data, environmental factors, and deterioration trends, AI predicts when structural elements may need repair or replacement—feeding back valuable insights into future design planning.

Key Benefits of Using AI in Structural Engineering

Time Savings – AI dramatically reduces the time needed to explore design alternatives and perform iterative analyses.

Cost Efficiency – By optimizing material usage, layout, and member sizing, AI drives cost savings without compromising safety.

Enhanced Safety and Reliability – Predictive analytics and automated checks catch errors early, improving overall structural performance.

Sustainability Gains – Optimizing for reduced materials or embodied carbon supports sustainable construction goals.

Innovation Enablement – With AI generating design alternatives, engineers are free to focus more on creativity, value engineering, and strategic decisions.

Data-Driven Decision Making – AI uses large data sets (past projects, codes, sensor data) enabling more informed decisions rather than relying exclusively on intuition.

Steps to Implement AI-Driven Structural Engineering Processes

Here is a practical roadmap for integrating AI into structural engineering planning:

A. Define Objectives and Use Cases

Begin by identifying which parts of your workflow would benefit most from AI—whether conceptual design, member sizing, code compliance, or life-cycle analysis. Set clear goals (e.g., reduce design time by 30 %, cut material cost by 20 %, improve seismic performance margin by 15 %).

B. Data Collection and Preparation

AI requires quality data. Gather historical structural designs, performance outcomes, material properties, code documents, sensor data from existing structures, and BIM models. Clean, annotate, and structure this data to train AI models.

C. Select Appropriate AI Tools

Choose software or platforms that offer machine learning, generative design, optimization algorithms, and BIM integration. Evaluate compatibility with your existing CAD, FEM (Finite Element Method) or BIM tools, and workflow.

D. Train and Validate Models

Feed your data into machine learning or generative tools, train models to learn design patterns, constraints, performance outcomes, and code compliance. Validate the results with real-world projects or known benchmarks to ensure reliability.

E. Integrate into Design Workflow

Embed AI modules into your engineering workflow—link AI output into your BIM or FEM environment, ensure smooth hand-off between AI proposals and manual engineer review. Train staff on new tools and workflows.

F. Iterate and Refine

Engineering design is seldom done in one pass. Use AI’s capability for rapid iteration: generate alternatives, evaluate performance, refine goals, and repeat. With each cycle, the model’s accuracy and usefulness improve.

G. Monitor, Maintain and Upgrade

Post-construction, collect performance data from sensors, maintenance logs and actual behavior. Feed this data back into the AI system to improve its predictive power for future projects. Continually update the AI model to reflect new codes, materials, and construction methods.

Challenges and Considerations

While AI offers significant advantages, several challenges must be managed:

Quality of Data: Without high-quality, well-structured data, AI models risk producing unreliable or misleading results.

Interpretability: Engineers must understand how AI arrived at particular design recommendations; “black box” decisions may undermine trust or fail regulatory review.

Integration with Existing Workflows: Introducing AI often requires changes to software, processes, and staff skills. Resistance to change and training needs must be addressed.

Regulatory Acceptance: Building codes and engineering approvals may not yet explicitly address AI-designed structures; engineers must ensure compliance and be ready to provide traditional calculations.

Ethics and Safety: Structural failure carries huge implications—engineers must validate AI outputs thoroughly and never over-rely on automation without human oversight.

Cost of Implementation: Though ROI can be strong, initial investment in software, data infrastructure, training, and model development can be significant.

Real-World Applications and Use Cases

In high-rise buildings in seismic zones, engineers have used AI-driven generative design to optimize bracing systems, achieving both improved performance and lower material usage.

In bridge design, AI algorithms assist in selecting optimal beam depths and spans based on live load, material cost, and environmental exposure.

For rehabilitation of old structures, AI analyses sensor data to forecast deterioration, informing retrofit planning and maintenance scheduling.

In modular construction, AI helps in rapidly assembling structural modules or frames by optimizing connection layouts and module geometry for transport constraints and onsite assembly time.

Best Practices for Engineers and Firms

To make the most of AI in structural engineering planning, consider the following best practices:

Ensure cross-discipline collaboration: structural, architectural, MEP (Mechanical, Electrical & Plumbing) engineers, contractors and BIM managers should engage early.

Maintain human-in-the-loop oversight: AI should augment—not replace—engineer judgement. Engineers remain accountable for safety, compliance and constructability.

Use incremental adoption: Begin with a pilot project or limited use-case; scale up once benefits and workflows are proven.

Invest in training and culture change: Engineers must understand AI workflows, data limitations, and how to interpret results.

Maintain version control and traceability: Keep track of AI-generated iterations, design decisions, and rationale so you can defend outcomes during approvals or variations.

Keep security and data governance strong: Sensitive structural and project data must be managed properly—especially when using cloud-based AI platforms.

Stay up-to-date with regulations: As AI becomes more prevalent, codes and standards may evolve; stay ahead of compliance requirements.

The Future of Structural Engineering Plans with AI

Looking ahead, the convergence of AI with other technologies promises further transformation:

Digital twins of entire structures will allow real-time simulation and optimization, continuously feeding back from sensors to AI models.

Augmented reality (AR) and virtual reality (VR) will let engineers visualize AI-generated structural systems in immersive environments before breaking ground.

Autonomous construction robotics may integrate with AI-optimized plans, enabling on-site automated assembly with minimal human intervention.

Sustainability-driven AI will increasingly optimize designs for low-carbon materials, reuse, life-cycle assessment, and circular construction.

Collaborative AI platforms will enable multiple stakeholders (engineers, architects, contractors, fabricators) to co-create structural solutions in real time, leveraging AI to converge on optimal outcomes faster.

Conclusion

Artificial intelligence is not merely a futuristic option for structural engineering—it is rapidly becoming a practical, high-value tool. For structural engineers and firms willing to invest in data, tools, and process change, AI offers significant benefits: faster design cycles, better-performing structures, cost savings, and greater innovation. However, success depends on thoughtful implementation, human oversight, regulatory awareness, and continuous learning. By embracing AI thoughtfully, structural engineering planning can reach new heights of efficiency, resilience and sustainability.