Digital Twins Are Transforming AEC Firm Futures

The Architecture, Engineering, and Construction (AEC) industry has long been characterized by fragmentation, cost overruns, schedule delays, and a persistent productivity gap compared to other sectors. While Building Information Modeling (BIM) laid the groundwork for digitalization, the true revolution is now being catalyzed by Digital Twin technology. A Digital Twin is not merely a static 3D model; it is a dynamic, living, virtual replica of a physical asset—a building, a bridge, or an entire city—that is continuously updated with real-time data from its physical counterpart.

This transformative technology is fundamentally changing how AEC firms design, build, and operate assets. By creating a fully integrated, data-driven environment, Digital Twins offer an unprecedented opportunity to eliminate waste, mitigate risk, optimize asset performance, and unlock entirely new revenue streams throughout the entire Asset Lifecycle. For firms seeking a competitive edge, robust SEO positioning, and superior financial outcomes, adopting a comprehensive Digital Twin strategy is no longer optional—it is essential for survival in the emerging Construction 4.0 era.

This extensive article delves into the profound impact of Digital Twins across the AEC project continuum, from initial design to final demolition, detailing the mechanics, strategic advantages, critical technologies, and significant challenges involved in mastering this revolutionary discipline.

Defining the Digital Twin: Beyond the BIM Model

To grasp the power of a Digital Twin, it is crucial to differentiate it from its predecessor, the BIM model, which serves as its foundational geometry and information hub.

The Core Components of a True Digital Twin

A true Digital Twin is a sophisticated cyber-physical system characterized by a loop of constant data exchange between the physical asset and its virtual counterpart. It requires three core components:

A. The Physical Asset: The real-world structure, system, or facility (the “thing” being twinned). This asset is outfitted with sensors, meters, and monitoring equipment.

B. The Digital Replica (The Model): The high-fidelity virtual representation, often initiated from a Level of Detail (LOD) 500 BIM model, which includes all geometry, spatial relationships, and asset information (manufacturer, lifecycle data, material).

C. The Data Connection and Platform: The critical link established through Internet of Things (IoT) sensors, Supervisory Control and Data Acquisition (SCADA) systems, and specialized cloud platforms. This connection ensures that real-time performance data (temperature, pressure, energy consumption, vibration) flows instantly from the physical asset to the digital model, making the replica “live” and dynamic. This flow enables the Digital Twin to reflect the asset’s current state, history, and predicted future state.

The Digital Twin Maturity Continuum

Digital Twins are not a single product but rather a continuum of sophistication. Firms progress through maturity levels, gaining increasing value at each stage:

A. Descriptive Twin (Static): This is essentially the As-Built BIM model handed over at project completion. It contains rich information but is static and not connected to live data. It documents the asset’s state at a point in time.

B. Informative Twin (Connected): This twin integrates real-time data from basic sensors (e.g., energy meters) into the BIM model. It allows facility managers to monitor the asset’s current performance and easily locate physical components via the model.

C. Predictive Twin (Intelligent): This level incorporates Artificial Intelligence (AI) and Machine Learning (ML) to analyze historical and live data. It can simulate future conditions, forecast equipment failure, and predict the impact of changes (e.g., increased occupancy) on energy use, moving operations from reactive to proactive.

D. Comprehensive Twin (Autonomous): The highest level, where the Digital Twin not only predicts issues but automatically implements solutions by sending commands back to the physical asset’s control systems (e.g., automatically adjusting HVAC setpoints to optimize energy consumption based on weather forecasts and predicted occupancy). This represents true autonomous asset management.

Transformative Impact Across the AEC Lifecycle

The value proposition of Digital Twins spans all phases of a project, creating efficiencies and reducing risks that traditional methods could not touch.

1. Design and Pre-Construction Optimization

In the initial stages, Digital Twins allow for unprecedented levels of testing and optimization before any physical work begins.

A. Advanced Performance Simulation: Engineers use the Digital Twin to run complex simulations for factors like structural integrity, thermal performance, airflow dynamics, and natural lighting under various, realistic environmental conditions (e.g., extreme weather events). This allows designers to test hundreds of design iterations virtually, optimizing materials and systems for durability and energy efficiency from day one.

B. Early Conflict Detection (4D/5D Modeling): The Digital Twin expands upon traditional BIM by integrating the dimension of time (4D) and cost (5D). It allows project managers to simulate the entire construction sequence, identifying potential scheduling conflicts, site logistics bottlenecks (crane placement, material delivery routes), and clash detection between trades before they cause costly on-site delays and rework.

C. Stakeholder Alignment and Visualization: Digital Twins serve as a single, shared source of truth. By integrating the model with Virtual Reality (VR) and Augmented Reality (AR), stakeholders—including clients, regulatory bodies, and end-users—can immerse themselves in the future building, providing intuitive feedback and achieving sign-off much faster than with 2D drawings or static renderings.

2. Construction and Project Execution Efficiency

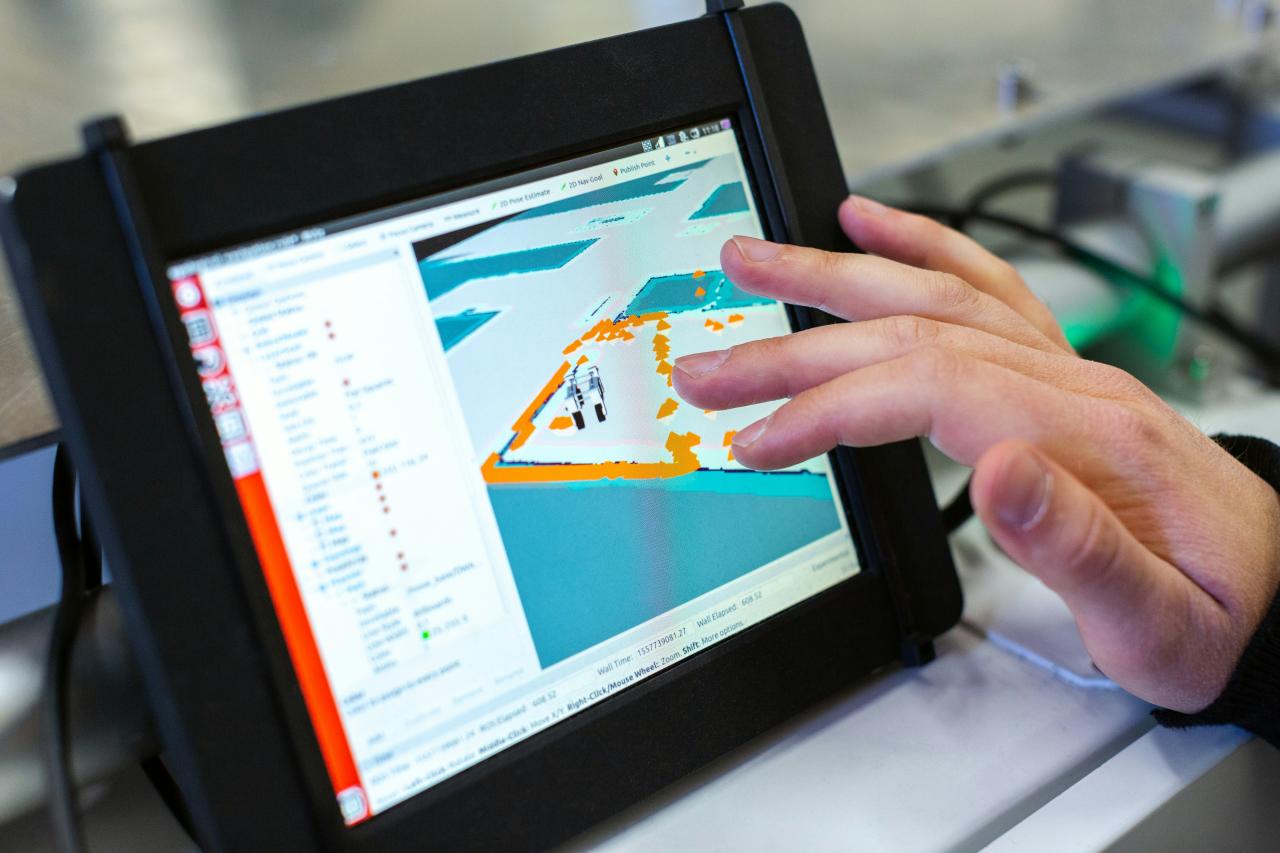

During the actual building process, the Digital Twin evolves into a Construction Twin, acting as a real-time command center for the site.

A. Real-Time Progress Monitoring: Data captured from drones, laser scanners, and site cameras is fed into the twin, providing a live comparison of the As-Built progress against the As-Designed model. This allows project managers to instantly detect deviations, quality assurance issues, and schedule slippages, facilitating immediate corrective action rather than costly discovery weeks later.

B. Optimized Resource Allocation: IoT devices track the location and utilization of heavy machinery, tools, and even personnel. The Digital Twin uses this data to identify bottlenecks in workflow, monitor equipment downtime, and dynamically adjust labor and material logistics, ensuring that resources are always precisely where they are needed to maximize productivity. Studies suggest Digital Twins can reduce rework and construction waste by over 10% to 15%.

C. Enhanced Site Safety and Risk Management: Sensors monitor site conditions, identifying hazards like excessive dust, dangerous noise levels, or structural movements. The Digital Twin can overlay safety protocols onto the live site map and issue immediate, automated alerts when workers enter high-risk zones or when sensor readings exceed safe thresholds, contributing significantly to improved Environmental, Health, and Safety (EHS) compliance.

3. Operations, Maintenance, and Asset Management

The greatest and longest-lasting value of the Digital Twin is realized in the Operations and Maintenance (O&M) phase, which typically accounts for up to 80% of a facility’s total lifecycle cost.

A. Predictive Maintenance (PdM): The twin monitors the health of critical equipment (HVAC units, elevators, pumps) using integrated sensors. ML algorithms analyze vibration, temperature, and usage patterns to predict precisely when a component is likely to fail. This allows facility managers to schedule maintenance just before a failure occurs, eliminating expensive, disruptive emergency repairs and maximizing the operational lifespan of assets.

B. Energy Consumption Optimization: By linking the Digital Twin to the Building Management System (BMS) and integrating external data (weather forecasts, utility pricing), the twin can autonomously adjust HVAC, lighting, and power systems in real-time. This sophisticated optimization can yield energy savings of 15% to 35% annually, contributing directly to a higher Net Operating Income (NOI) and increased asset value.

C. Rapid Diagnostics and Troubleshooting: When an issue occurs (e.g., a cold spot in an office floor), facility managers can instantly view the Digital Twin to identify the exact location of the associated air handler, its maintenance history, and the surrounding pipe or ductwork without physically opening walls or ceilings. This dramatically reduces the time and cost associated with troubleshooting and repair.

Critical Enabling Technologies and Interoperability

Critical Enabling Technologies and Interoperability

The sophistication of the Digital Twin relies heavily on the convergence of several cutting-edge technologies. Success hinges on ensuring seamless interoperability between these diverse systems.

The Technology Stack

A. Building Information Modeling (BIM): BIM models provide the geospatial and geometric foundation for the twin. They are the initial repository of all asset information, including metadata required for lifecycle management. Advanced authoring tools are essential for creating the highly detailed (LOD 500) models necessary for effective twinning.

B. Internet of Things (IoT) and Industrial IoT (IIoT): These sensors—measuring everything from occupancy and air quality to equipment vibration and structural strain—are the nervous system of the Digital Twin, providing the continuous, low-latency stream of data that keeps the model live.

C. Cloud Computing and Data Analytics: Massive volumes of real-time data must be stored, processed, and analyzed. Cloud platforms provide the scalable infrastructure needed, while Big Data Analytics tools (including ML models) extract actionable insights, such as performance predictions and anomaly detection, from the raw sensor data.

D. Geospatial Technologies (GIS): For infrastructure, campus, and city-scale twins (Urban Digital Twins), integration with Geographic Information Systems (GIS) is vital. GIS provides the real-world context, elevation data, regulatory boundaries, and utility mapping necessary to ground the building model within its larger operational environment.

The Interoperability Challenge

The biggest technical hurdle is ensuring that data can flow freely between proprietary software systems (BIM tools, CAD, ERP systems, BMS platforms, IoT dashboards). This requires adherence to open standards and the use of middleware or specialized Digital Twin Platforms (DTPs) designed explicitly to normalize, categorize, and link disparate data sources using common ontologies and data dictionaries.

Strategic Challenges and the Path to Adoption

While the rewards of Digital Twins are immense, AEC firms face significant organizational, technical, and financial challenges in adoption. Addressing these requires a top-down strategic commitment.

Financial and Technical Barriers

A. High Initial Investment Costs: The financial commitment required for hardware (sensors, scanners), specialized software licenses (DTPs), cloud infrastructure, and the initial process of retrofitting existing assets with IoT can be substantial, often posing a barrier for smaller firms or projects with tight capital expenditure budgets.

B. Data Quality and Governance: A Digital Twin is useless—or worse, actively misleading—if it is built on poor-quality data. Ensuring data is accurate, complete, correctly classified, and continuously updated requires strict Data Governance policies and consistent data quality checks throughout the entire design and construction process. Garbage In, Garbage Out (GIGO) is a critical risk.

C. Talent Acquisition and Upskilling: The successful deployment of a Digital Twin requires a fusion of skills: data science, cloud architecture, BIM expertise, and traditional engineering. There is a massive global shortage of professionals who possess this unique blend of expertise. AEC firms must commit to internal upskilling and collaboration between IT, engineering, and operations departments.

Organizational and Process Overhauls

A. Collaboration Across the Value Chain: Digital Twins demand that architects, engineers, contractors, and facility owners share data transparently and collaboratively throughout all phases of the project. This requires breaking down traditional siloes and forging new, integrated commercial agreements that incentivize data sharing rather than data hoarding.

B. Shifting Traditional Workflows: The introduction of real-time data monitoring changes fundamental workflows. Site managers must learn to trust and react to data from the twin rather than solely relying on visual inspections or paper reports. This change management requires strong executive sponsorship and clearly defined Key Performance Indicators (KPIs) based on twin-generated insights.

C. Security and Privacy Concerns: Since the Digital Twin integrates sensitive design, operational, and potentially personal (occupancy) data, it becomes a high-value target for cyber-attackers. Robust Cybersecurity protocols, including granular access controls and encryption for all data streams, are absolutely essential to protect both the firm and the client’s asset integrity.

The Future: Autonomous Assets and Smart Cities

The ultimate trajectory of the Digital Twin in AEC extends far beyond single buildings, leading to the creation of truly Smart Infrastructure and Smart Cities.

From Building to Ecosystem

A. Urban Digital Twins: These massive-scale twins model entire urban areas, integrating data from individual buildings, traffic systems, utility grids, and environmental sensors. Urban Digital Twins are already being used by city planners to simulate the impact of new developments, optimize public transportation, model disaster response scenarios, and manage resources like water and power across the entire metropolis.

B. Integration with AI for Autonomous Control: In the near future, the highest-maturity Digital Twins will move toward autonomy. AI models will not just recommend actions; they will execute them. For instance, a Smart Traffic Twin could autonomously adjust all traffic light timings across a city sector in real-time to manage congestion resulting from an unforeseen accident, vastly improving urban efficiency without human intervention.

C. Sustainable Design and Resilience: Digital Twins are powerful tools for achieving Net-Zero goals. By continuously monitoring the energy performance and waste output of assets, they provide the granular data necessary to meet strict sustainability certifications and regulatory mandates, enhancing the long-term environmental value and market appeal of AEC projects.

Conclusion: Securing the Competitive Advantage

Conclusion: Securing the Competitive Advantage

The integration of Digital Twins represents the most significant technological leap for the Architecture, Engineering, and Construction industry since the advent of BIM. This technology offers an unparalleled opportunity to bridge the gap between the physical and digital worlds, creating a feedback loop that drives continuous, measurable improvement in design, construction speed, cost control, and operational efficiency.

For AEC firms, mastering this technology is crucial for gaining and maintaining a competitive advantage. It secures superior project predictability, reduces exposure to high-cost risks like rework and equipment failure, and unlocks new, highly profitable services in the long-term asset management space. By strategically addressing the challenges of data quality, interoperability, and talent, firms can effectively transition to a data-driven paradigm, establishing themselves as market leaders poised to thrive in the inevitable future of Construction 4.0 and securing their position in the high-value content niche for years to come.

Critical Enabling Technologies and Interoperability

Critical Enabling Technologies and Interoperability Conclusion: Securing the Competitive Advantage

Conclusion: Securing the Competitive Advantage