The construction industry, long perceived as a bastion of tradition and manual labor, is on the cusp of a profound transformation. Driven by relentless demands for increased efficiency, enhanced safety, higher quality, and sustainable practices, the sector is increasingly embracing advanced technologies. At the forefront of this revolution is robotics in building, marking the dawn of a truly new era for how we conceive, construct, and manage our built environment. This isn’t merely about replacing human workers; it’s about augmenting human capabilities, automating repetitive and dangerous tasks, achieving unprecedented precision, and unlocking entirely new possibilities in design and fabrication, ultimately reshaping the very fabric of construction.

The Imperative for Automation: Why Construction Needs Robotics

The traditional construction industry faces a unique confluence of challenges that make the integration of robotics not just an innovation, but an urgent necessity. These pressures range from labor shortages to environmental demands and the relentless pursuit of project efficiency.

A. Addressing Labor Shortages and Skill Gaps

A pervasive issue plaguing the global construction sector is a severe and worsening shortage of skilled labor. An aging workforce, a declining interest among younger generations in manual labor, and the physically demanding nature of construction work have created a widening gap between demand and supply.

- Aging Workforce Demographics: Many experienced construction workers are nearing retirement, taking with them decades of invaluable knowledge and skills. This demographic shift leaves a void that new entrants are not filling at a sufficient pace.

- Lack of New Talent: The perception of construction as a difficult, dangerous, and low-tech career path deters younger individuals. There’s a global struggle to attract and retain new talent, particularly for specialized trades.

- Physical Demands and Safety Concerns: Construction remains one of the most hazardous occupations globally. The strenuous physical demands, exposure to extreme weather, and high risk of accidents contribute to worker burnout and injury, further exacerbating labor retention issues. Robotics can perform these dangerous, repetitive, or physically taxing tasks, protecting human workers.

B. Driving Enhanced Efficiency and Productivity

Despite technological advancements in other sectors, construction has notoriously lagged in productivity improvements. Traditional methods are often inefficient, leading to project delays and cost overruns.

- Manual Repetition: Many construction tasks, such as bricklaying, welding, rebar tying, and certain types of assembly, involve highly repetitive motions. These tasks are prone to human error over long periods and are ideal candidates for robotic automation, which can perform them tirelessly and consistently.

- Speed of Execution: Robots can operate continuously, often at higher speeds and with greater consistency than human workers, significantly accelerating project timelines, especially for large-scale or modular construction projects.

- Reduced Waste: Precision robotics minimizes material waste by executing tasks with extreme accuracy, cutting materials precisely, and optimizing usage patterns. This has direct cost savings and environmental benefits.

- Optimized Workflows: Robotics necessitates a more digitized and planned workflow, from design to fabrication, which in turn optimizes the entire construction process, reducing idle time and improving coordination.

C. Elevating Quality and Precision

Human craftsmanship, while invaluable, is inherently subject to variability. Robotics offers a path to unprecedented levels of accuracy and consistency, directly impacting the final quality of a structure.

- Sub-Millimeter Accuracy: Construction robots, especially those integrated with digital models (BIM – Building Information Modeling), can achieve sub-millimeter precision in tasks like laying bricks, welding joints, or placing components. This dramatically reduces errors and improves structural integrity.

- Consistent Output: Unlike humans who can tire or lose focus, robots maintain consistent performance and quality throughout their operational cycles, ensuring uniformity across large projects.

- Complex Geometries: Robots can execute complex, non-standard geometries and intricate designs that would be extremely challenging, time-consuming, or even impossible for human workers to achieve manually, unlocking new architectural possibilities.

D. Fostering a Safer Work Environment

Construction sites are inherently dangerous. Robotics offers a significant opportunity to mitigate risks and improve worker safety.

- Hazardous Tasks: Robots can be deployed to perform tasks in hazardous environments, such as working at heights, in confined spaces, with heavy loads, or in areas with toxic materials, thereby removing human workers from harm’s way.

- Reduced Repetitive Strain Injuries: Automating repetitive and ergonomically challenging tasks reduces the incidence of musculoskeletal disorders (MSDs) and other long-term injuries among human workers, leading to healthier and more sustainable careers.

- Controlled Environments: Much robotic construction takes place off-site in controlled factory environments (prefabrication/modular construction), which are inherently safer and more predictable than dynamic, open construction sites.

E. Driving Sustainability and Environmental Responsibility

With increasing global focus on climate change, the construction industry is under pressure to adopt more sustainable practices. Robotics contributes significantly to this goal.

- Material Optimization: As mentioned, precise robotic fabrication minimizes material waste, which directly reduces the carbon footprint associated with material production and transportation.

- Energy Efficiency: Automated processes can be optimized for energy consumption. Furthermore, robots can help construct buildings designed for higher energy efficiency more accurately.

- Reduced Emissions: Fewer human workers on-site and more efficient processes can lead to reduced reliance on diesel-powered equipment and transportation, lowering emissions.

- Recycling and Deconstruction: Robotics is also being explored for automated demolition and material sorting, facilitating more efficient recycling and reuse of construction waste.

Key Applications and Types of Robotics in Building

The integration of robotics into construction is not a singular phenomenon but rather a diverse array of applications, each tailored to specific tasks and stages of the building process.

A. On-Site Construction Robotics

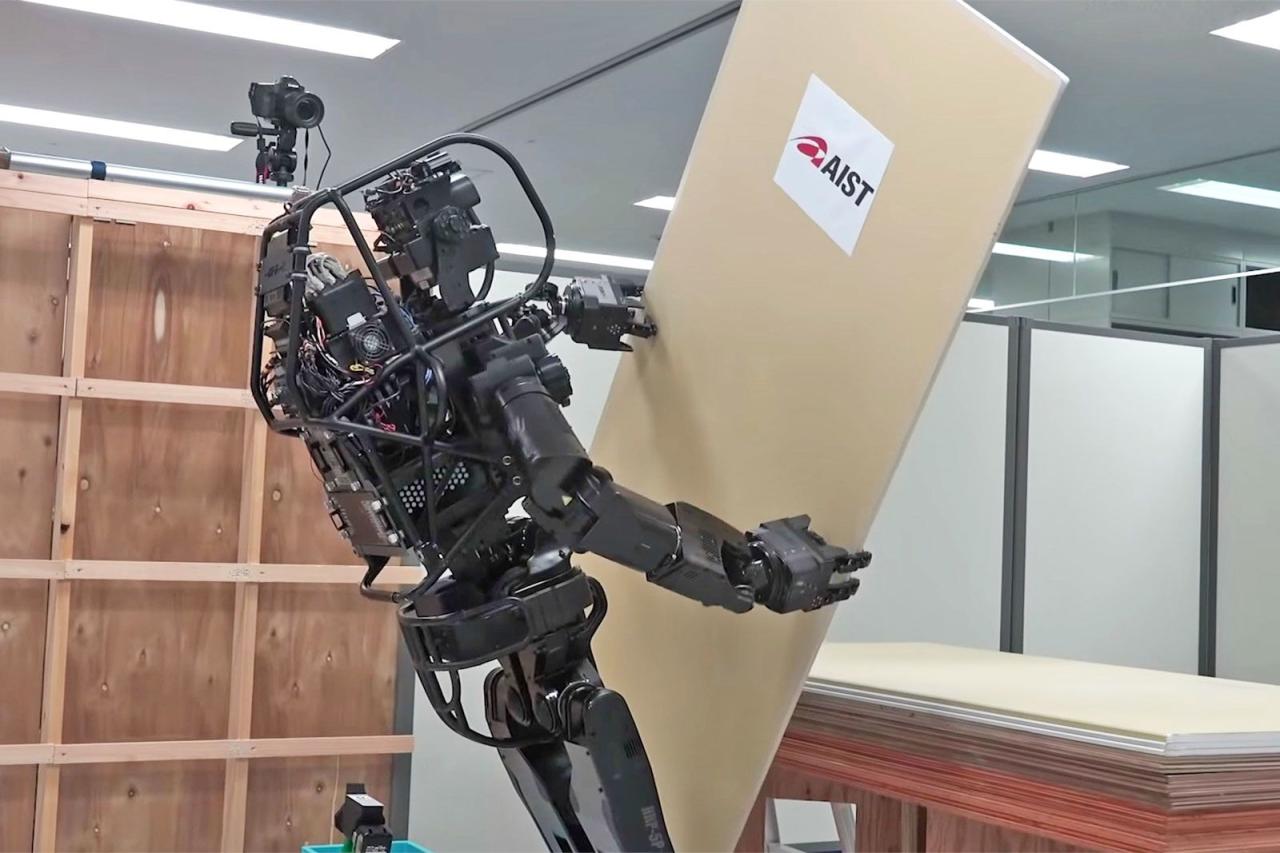

These robots are designed to operate directly on dynamic and often challenging construction sites, performing tasks that complement human labor.

- Autonomous Surveying and Mapping Robots:

- Drones (UAVs): Equipped with LiDAR, photogrammetry, and thermal cameras, drones autonomously survey sites, create 3D models, monitor progress, inspect structures for defects, and track material inventory.

- Ground Robotics: Autonomous ground vehicles can perform repetitive tasks like site layout, marking, and topographical mapping, often integrated with GPS and BIM data for precision.

- Heavy Equipment Automation:

- Autonomous Excavators/Dozers: Self-driving heavy machinery capable of performing tasks like digging, grading, and moving earth based on pre-programmed digital models. This enhances safety and precision, especially in hazardous conditions.

- Robotic Demolition: Specialized robots, often remote-controlled, that can safely and efficiently demolish structures in dangerous or confined spaces, reducing risk to human operators.

- Material Handling and Placement Robots:

- Robotic Bricklayers: Machines capable of laying bricks with extreme precision and speed, following digital blueprints, such as Hadrian X by FBR Limited.

- Rebar Tying Robots: Automated systems that tie rebar connections much faster and more consistently than manual methods, critical for reinforced concrete structures.

- Robotic Welding Systems: Used for precise and high-quality welding in structural steel fabrication, both on-site and in off-site factories.

- Autonomous Mobile Robots (AMRs): Used for transporting materials around large construction sites, improving logistics and reducing manual hauling.

- 3D Printing Robots:

- Construction 3D Printers: Large-scale robotic systems that can extrude concrete, polymers, or other materials layer by layer to construct walls, homes, or even entire buildings. This technology holds immense promise for rapid, customizable, and low-cost construction, particularly for affordable housing or disaster relief. Examples include ICON, COBOD.

B. Off-Site Fabrication and Modular Construction Robotics

The most significant immediate impact of robotics is seen in controlled factory environments, where precision and efficiency can be maximized. This underpins the growth of modular and prefabricated construction.

- Robotic Assembly Lines: Factories utilize industrial robots (e.g., robotic arms) for precise cutting, welding, drilling, and assembly of building components (e.g., wall panels, floor modules, bathroom pods). This parallelizes construction, enabling components to be built simultaneously off-site while site work proceeds.

- Automated Material Handling: Robots manage the movement and positioning of heavy and awkward materials within the factory, optimizing workflow and enhancing safety.

- Digital Fabrication: Robots directly translate digital designs (from BIM software) into physical components with extreme accuracy, reducing errors and enabling complex bespoke designs to be mass-produced.

- Quality Control Robotics: Robots equipped with vision systems and sensors perform automated quality checks on fabricated components, ensuring they meet specifications before being transported to the construction site.

C. Collaborative Robots (Cobots)

A growing trend is the use of cobots, which are designed to work safely alongside human workers, sharing tasks and augmenting human capabilities.

- Assisted Lifting/Placement: Cobots can assist workers with heavy lifting and precise placement of components, reducing physical strain and improving accuracy.

- Tool Handling and Guidance: Cobots can hold tools or guide human workers through complex assembly sequences, providing real-time feedback and assistance.

- Repetitive Tasks: They can handle repetitive, mundane tasks, freeing up human workers for more complex problem-solving, quality assurance, or skilled craftsmanship.

Integrating Robotics: The Digital Foundation and Ecosystem

The effective deployment of robotics in building is not just about the robots themselves. It relies heavily on a robust digital ecosystem that enables seamless data flow and intelligent decision-making.

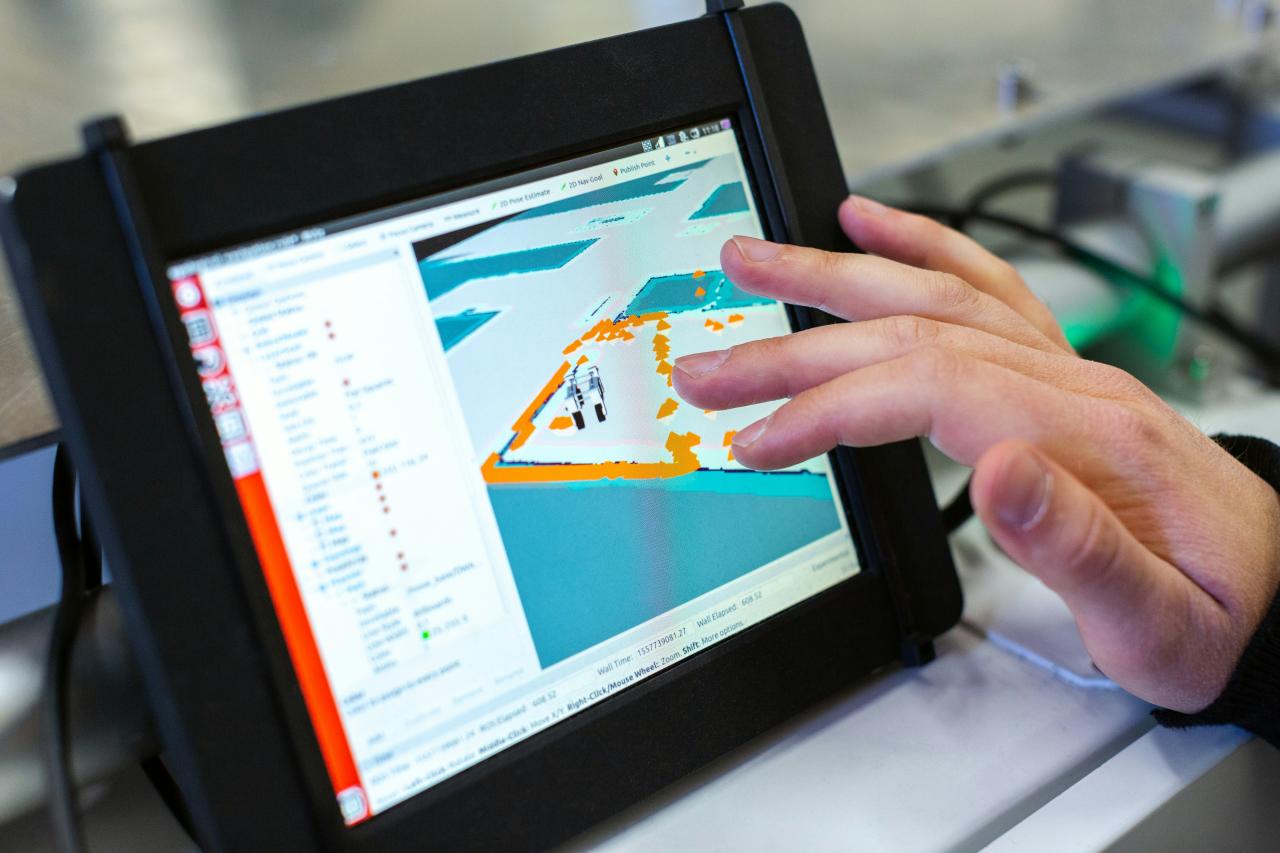

A. Building Information Modeling (BIM)

BIM is the digital backbone of modern, robotic-assisted construction. It creates a comprehensive, intelligent 3D model of a building, incorporating architectural, structural, MEP (mechanical, electrical, plumbing), and other data.

- Single Source of Truth: BIM provides a centralized, single source of truth for all project information, ensuring consistency between design and execution.

- Robot Programming: Robots are directly programmed using data extracted from BIM models, ensuring precise execution of design intent. Changes in the BIM model can automatically update robotic fabrication instructions.

- Clash Detection and Optimization: BIM enables early detection of clashes (e.g., pipes going through beams) and allows for design optimization before construction begins, reducing costly on-site rework.

- Progress Monitoring: Drones and ground robots can scan actual site conditions and compare them against the BIM model to monitor progress and identify deviations.

B. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are rapidly becoming integral to optimizing robotic construction processes.

- Robotic Vision and Navigation: AI-powered computer vision allows robots to understand their environment, recognize objects, detect anomalies, and navigate complex, dynamic construction sites autonomously.

- Predictive Maintenance: ML algorithms analyze sensor data from robots and equipment to predict potential failures, enabling proactive maintenance and minimizing downtime.

- Construction Planning and Optimization: AI can optimize project schedules, resource allocation, and logistics, considering real-time site conditions and material availability.

- Quality Assurance: ML models can analyze sensor data or images from robotic inspections to automatically identify defects or deviations from quality standards.

C. Data Analytics and Cloud Platforms

The massive amounts of data generated by robotic equipment and sensors on a construction site or in a factory are invaluable for continuous improvement.

- Performance Monitoring: Real-time data analytics provides insights into robotic performance, efficiency, and utilization rates, allowing for optimization.

- Process Optimization: Analyzing data from robotic operations helps identify bottlenecks, improve workflows, and refine manufacturing processes in off-site fabrication.

- Digital Twins: Creating digital replicas (digital twins) of buildings and ongoing construction processes allows for real-time monitoring, simulation, and predictive analysis, integrating data from robots and other sources.

D. Connectivity (5G, IoT)

Robust and low-latency connectivity is crucial for controlling autonomous robots and transmitting large volumes of data.

- 5G Networks: The rollout of 5G provides the high bandwidth and low latency necessary for real-time control of autonomous heavy machinery and seamless data transfer from remote sensors and robots.

- IoT Sensors: Integrating IoT sensors into materials, equipment, and structures provides continuous data feeds that can inform robotic actions, monitor curing processes, or detect structural anomalies.

The Transformative Impact and Future Outlook

The integration of robotics is not just an incremental improvement; it promises a fundamental reshaping of the construction industry, with far-reaching implications for its stakeholders and the built environment.

A. Redefining Construction Work and Roles

Robotics will undoubtedly change the nature of construction jobs. While some manual, repetitive tasks may be automated, it will also create new roles and demand new skills.

- Upskilling and Reskilling: There will be a greater need for workers skilled in operating, programming, maintaining, and supervising robots. This requires investment in training and education programs focused on digital construction skills.

- Human-Robot Collaboration: The future of construction is likely to be a collaborative environment where humans work alongside robots, with robots handling heavy, dangerous, or monotonous tasks, and humans focusing on complex problem-solving, quality control, supervision, and intricate finishing work.

- Shift to Off-Site Roles: As prefabrication and modular construction grow, more jobs will shift from volatile, outdoor construction sites to controlled, safer factory environments, potentially attracting a broader and more diverse workforce.

B. Enabling New Architectural Possibilities

Robotics liberates designers from the constraints of traditional construction methods.

- Complex Geometries: Architects can design highly complex, non-linear, and organic forms with the confidence that robots can precisely fabricate and assemble them.

- Parametric Design and Customization: Robotics, combined with parametric design software, allows for mass customization, where each building component can be uniquely adapted without incurring significant additional costs, leading to more responsive and context-specific architecture.

- Material Innovation: Robots can precisely handle and place novel materials, including new composites, recycled materials, or complex bio-materials, opening avenues for material innovation in building.

C. Accelerating Sustainable Construction Practices

Robotics is a powerful enabler for truly sustainable building.

- Circular Economy Principles: Robots can assist in precise deconstruction and sorting of materials for recycling and reuse, contributing to a circular economy in construction.

- Precision Resource Use: Minimized waste during fabrication and optimized energy usage during construction contribute directly to lower environmental impact throughout a building’s lifecycle.

- Local and On-Demand Construction: 3D printing robots, for example, enable construction using locally sourced materials with minimal waste, potentially even allowing for on-demand construction in remote areas or disaster zones.

D. The Rise of “Construction as a Service” and Digitized Supply Chains

The increasing automation and precision offered by robotics will foster new business models.

- Construction as a Service: Specialized robotic construction firms could offer services to traditional contractors, providing highly automated components or specific robotic task execution.

- Digitized Supply Chains: Integration of robots with BIM and IoT will lead to highly optimized, real-time supply chains, where materials are delivered precisely when and where they are needed, reducing storage costs and waste.

- Industrialized Construction: The industry will increasingly move towards an industrialized manufacturing model, akin to the automotive sector, with high levels of automation, quality control, and efficiency.

Challenges and Future Directions for Robotics in Building

Despite the immense promise, the widespread adoption of robotics in construction faces several significant challenges that require concerted effort from industry, academia, and policymakers.

A. High Initial Investment and ROI Justification

The upfront cost of acquiring sophisticated construction robots and integrating them into existing workflows can be substantial. Justifying the Return on Investment (ROI) can be challenging, especially for smaller firms or projects where the scale might not immediately warrant the expense.

B. Adaptability to Unpredictable Site Environments

While robots excel in controlled factory settings, construction sites are inherently dynamic, unstructured, and often unpredictable environments (weather changes, unexpected ground conditions, human movement). Developing robots that can truly adapt to this variability, self-correct, and operate safely alongside humans in real-time remains a significant technical hurdle (e.g., challenges in perception, navigation, and manipulation in chaotic settings).

C. Regulatory Frameworks and Safety Standards

Current regulatory frameworks and safety standards for robotics are often designed for industrial factories and may not directly apply or be sufficient for dynamic construction sites. Developing clear, consistent, and adaptable regulations for human-robot interaction and autonomous machinery on construction sites is crucial for widespread adoption.

D. Integration with Legacy Systems and Workflows

Many construction firms operate with legacy processes and software. Integrating advanced robotics, which rely heavily on digital data flow (BIM, IoT), with these existing systems and workflows can be complex and expensive, requiring significant investment in digital transformation initiatives.

E. Workforce Training and Cultural Resistance

Beyond the initial skill gap, there can be cultural resistance to adopting new technologies. Workers may fear job displacement, while management might be hesitant to invest in unproven technologies or disrupt established practices. Effective change management, comprehensive training programs, and demonstrating the benefits to the workforce are essential for successful integration.

F. Data Security and Privacy Concerns

As more construction processes become digitized and reliant on robotic data, data security and privacy become critical. Protecting sensitive project information, proprietary designs, and operational data from cyber threats is paramount, requiring robust cybersecurity measures and protocols.

Conclusion

The integration of robotics in building is not merely an incremental technological advancement; it signifies a fundamental paradigm shift that promises to redefine the entire construction industry. From addressing chronic labor shortages and vastly improving project efficiency to elevating quality, enhancing safety, and driving ambitious sustainability goals, the transformative potential of construction robotics is immense.

While challenges remain—particularly concerning initial investment, adaptability to unstructured environments, and the need for new regulatory frameworks and comprehensive workforce training—the trajectory is clear. As AI, advanced sensing, and collaborative robot technologies mature, they will increasingly become indispensable tools on every construction site and in every fabrication facility. The future of our built environment will be a testament to the synergistic collaboration between human ingenuity and robotic precision, creating safer, more efficient, higher-quality, and more sustainable structures for generations to come. The new era of construction is truly dawning, driven by the tireless innovation of robotics.